Slewing Bearing

Large bearings for heavy loads and rotational movement.

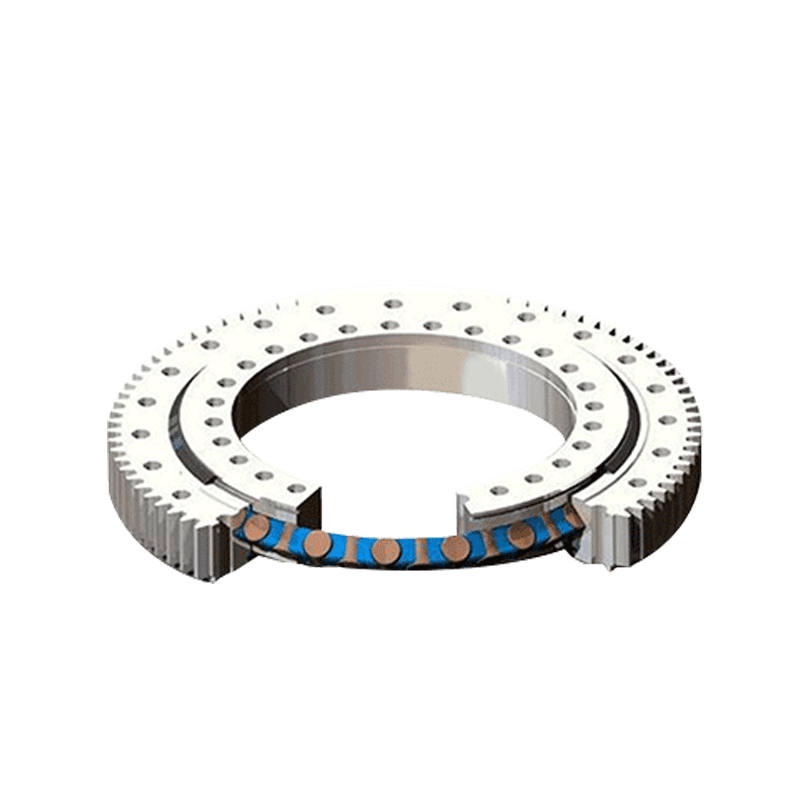

Structural Features

Round Design: Large ring structure with inner and outer rings housing rolling elements.

Rolling Elements: Spherical or cylindrical rollers arranged to support axial, radial, and moment loads.

Sealing Systems: Efficient seals protect against dust, water, and contaminants.

Gear System: Internal or external teeth enable rotation via gear mechanisms.

Structure Type

Slewing Bearing (Turntable Bearing) – Complete Guide

1. What is a Slewing Bearing?

A slewing bearing (also called a turntable bearing) is a large rolling bearing designed to support axial loads, radial loads, and tilting moments simultaneously while allowing slow rotation or oscillation. Unlike standard bearings, slewing bearings can carry very heavy loads and are widely used in construction machinery, industrial equipment, and renewable energy systems.

They are commonly installed in rotating parts of machinery, such as:

Tower crane slewing mechanisms

Excavator rotating platforms

Wind turbine yaw systems

2. Structure of a Slewing Bearing

A typical slewing bearing consists of the following components:

| Component | Function |

|---|---|

| Inner Ring | Supports the rotating part of the machinery and bears part of the load |

| Outer Ring | Fixed to the base or frame, supporting part of the load |

| Rolling Elements (Balls / Rollers) | Provide rolling contact and carry the load; can be four-point contact balls, crossed rollers, or cylindrical rollers |

| Cage | Separates and evenly spaces rolling elements to prevent collision |

| Seals | Protect against dust, water, and contaminants |

| Lubrication System (Grease / Oil) | Reduces friction and wear, prolonging service life |

3. Types of Slewing Bearings

3.1 Four-Point Contact Ball Slewing Bearing

Features: Steel balls contact the raceways at four points, capable of handling axial, radial, and tilting moment loads.

Advantages:

Simple structure, lightweight

Suitable for medium and small machinery

Applications:

Small tower cranes

Small excavators

Rotary tables in machinery

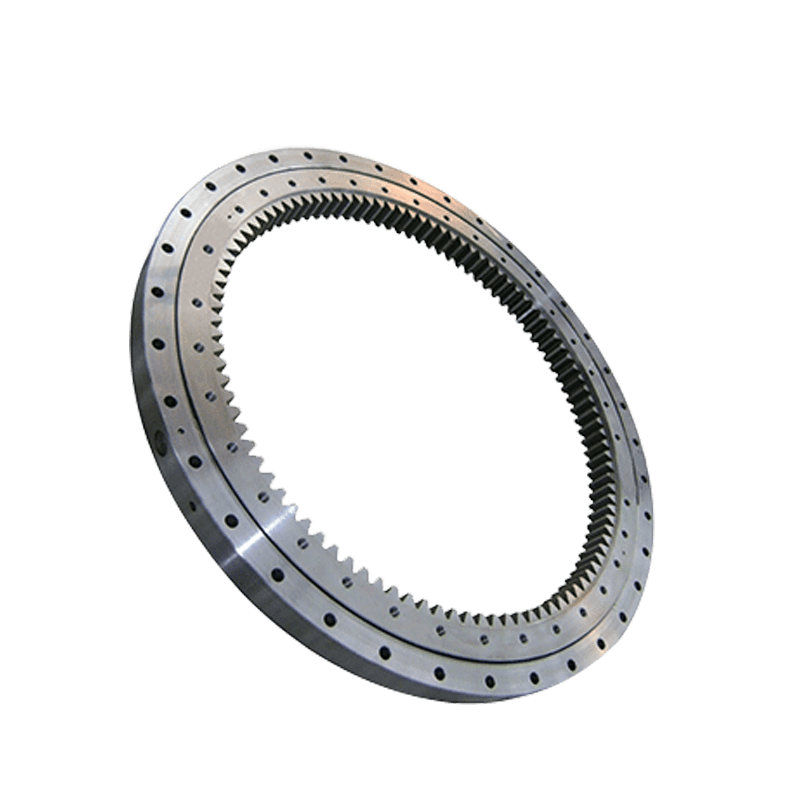

3.2 Crossed Roller Slewing Bearing

Features: Cylindrical rollers arranged perpendicular in alternating layers.

Advantages:

High rigidity

High precision with minimal backlash

Can handle significant tilting moments

Applications:

Robotic rotating joints

Precision machinery (CNC rotary tables)

Radar antennas and observation equipment

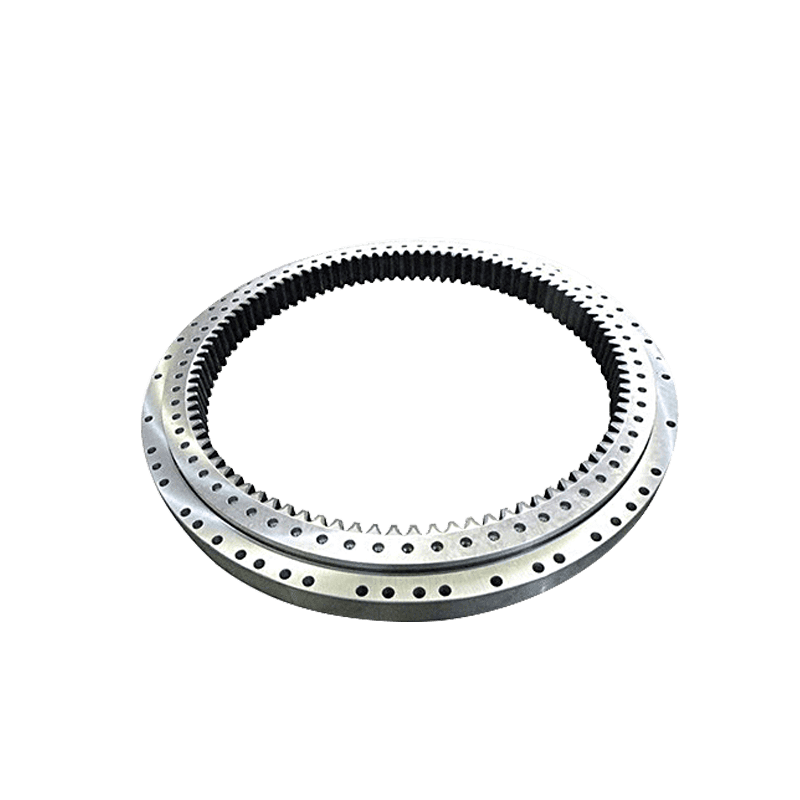

3.3 Three-Row Roller Slewing Bearing

Features: Three rows of rollers:

Radial rollers – carry radial loads

Axial rollers – carry axial loads

Moment rollers – carry tilting moments

Advantages:

Extremely high load capacity

Suitable for large cranes and heavy machinery

Applications:

Port container cranes

Large excavators

Wind turbine main bearings

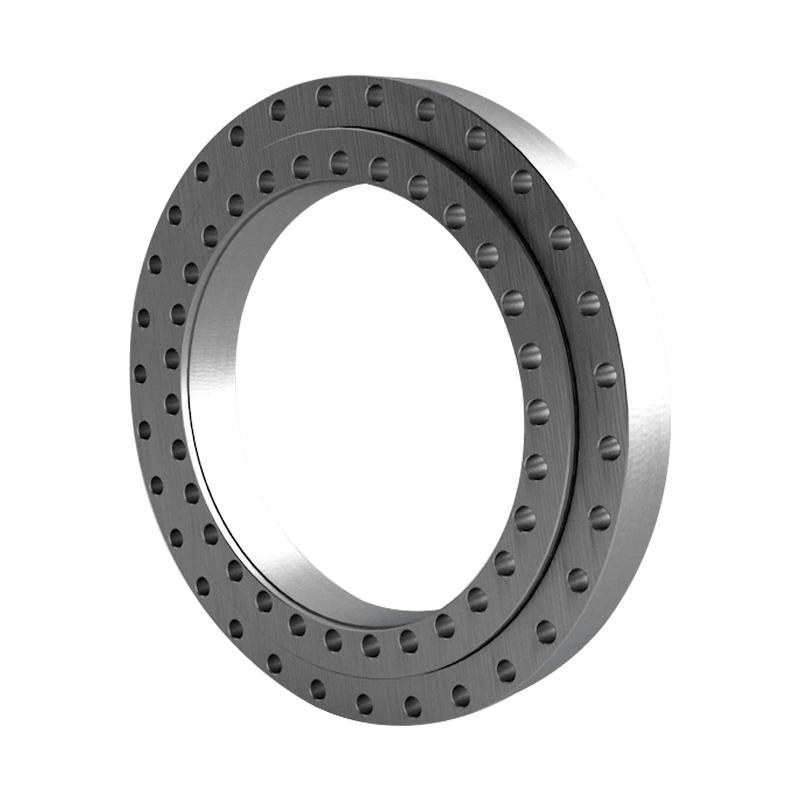

3.4 Double-Row Cylindrical / Ball Slewing Bearing

Features: Two rows of balls or rollers, suitable for medium loads with lower cost.

Applications:

Medium-sized machinery

Automated production line rotation systems

4. Selection Guidelines for Slewing Bearings

Key factors when selecting a slewing bearing:

| Parameter | Consideration |

|---|---|

| Load Type | Axial, radial, and tilting moment loads |

| Rotation Speed | Low-speed (excavators, cranes) or high-speed (precision machinery) |

| Environmental Conditions | Waterproof, dustproof, corrosion-resistant |

| Accuracy Level | General machinery or high-precision applications |

| Mounting Method | Bolt size, hole pattern, and mounting surface accuracy |

| Lubrication Method | Grease or circulating oil lubrication |

| Service Life | Theoretical life (L10 life) based on load and usage |

5. Applications of Slewing Bearings

Tower Cranes

High tilting moment required

Usually three-row roller or four-point contact ball bearings

Excavator Rotating Platforms

Supports machine weight and operational loads

Commonly four-point contact ball or three-row roller bearings

Wind Turbines

Yaw systems and blade adjustment

High precision and low friction

Typically crossed roller bearings

Port Cranes / Heavy Machinery

High load capacity required

Three-row roller bearings are preferred

6. Maintenance of Slewing Bearings

Regular Inspection:

Tighten bolts

Check rolling element wear

Inspect seal integrity

Lubrication:

Periodically add grease or oil according to manufacturer recommendations

Use high-pressure lubricants for heavy-load applications

Cleaning:

Remove dust, dirt, and water regularly

Prevent contaminants from entering the raceway

Temperature Monitoring:

Prevent overheating and ensure safe operation

Service Life Assessment:

Calculate theoretical life based on load

Replace or maintain in advance to avoid unexpected downtime

7. Advantages of Slewing Bearings

Can simultaneously support axial, radial, and tilting moment loads

Compact structure with high load capacity

Easy installation, wide range of applications

Customizable dimensions, precision, and materials (e.g., high-strength steel, corrosion-resistant steel)

Long service life with predictable maintenance intervals

8. Comparison of Slewing Bearing Types

| Bearing Type | Rolling Elements | Load Capacity | Rigidity | Precision | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| Four-Point Contact Ball | Steel Balls (4-point contact) | Medium axial, radial, and tilting moment | Medium | Medium | Small to medium tower cranes, excavators, rotary tables | Lightweight, simple structure, can handle combined loads | Not suitable for extremely heavy loads |

| Crossed Roller | Cylindrical Rollers arranged perpendicularly | Medium to high, mainly tilting moment | High | High | Robotic arms, CNC rotary tables, radar antennas | High rigidity, high precision, minimal backlash | Limited load capacity for very heavy machinery |

| Three-Row Roller | Three rows of cylindrical rollers (radial, axial, tilting) | Very high axial, radial, and tilting moment | Very high | Medium | Large port cranes, large excavators, wind turbines | Extremely high load capacity, suitable for very heavy equipment | Heavier, more expensive, requires precise mounting |

| Double-Row Ball / Roller | Two rows of balls or rollers | Medium load | Medium | Medium | Medium-sized machinery, automation systems | Cost-effective, simple design | Lower load capacity than 3-row or crossed roller types |

Quick Selection Tips:

Four-point contact ball → Medium load, small/medium machines, cost-effective.

Crossed roller → High precision, high rigidity, slower rotation, precision equipment.

Three-row roller → Very heavy load, large cranes, high tilting moment, long lifespan.

Double-row → Medium load, budget-friendly, simple machinery.

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

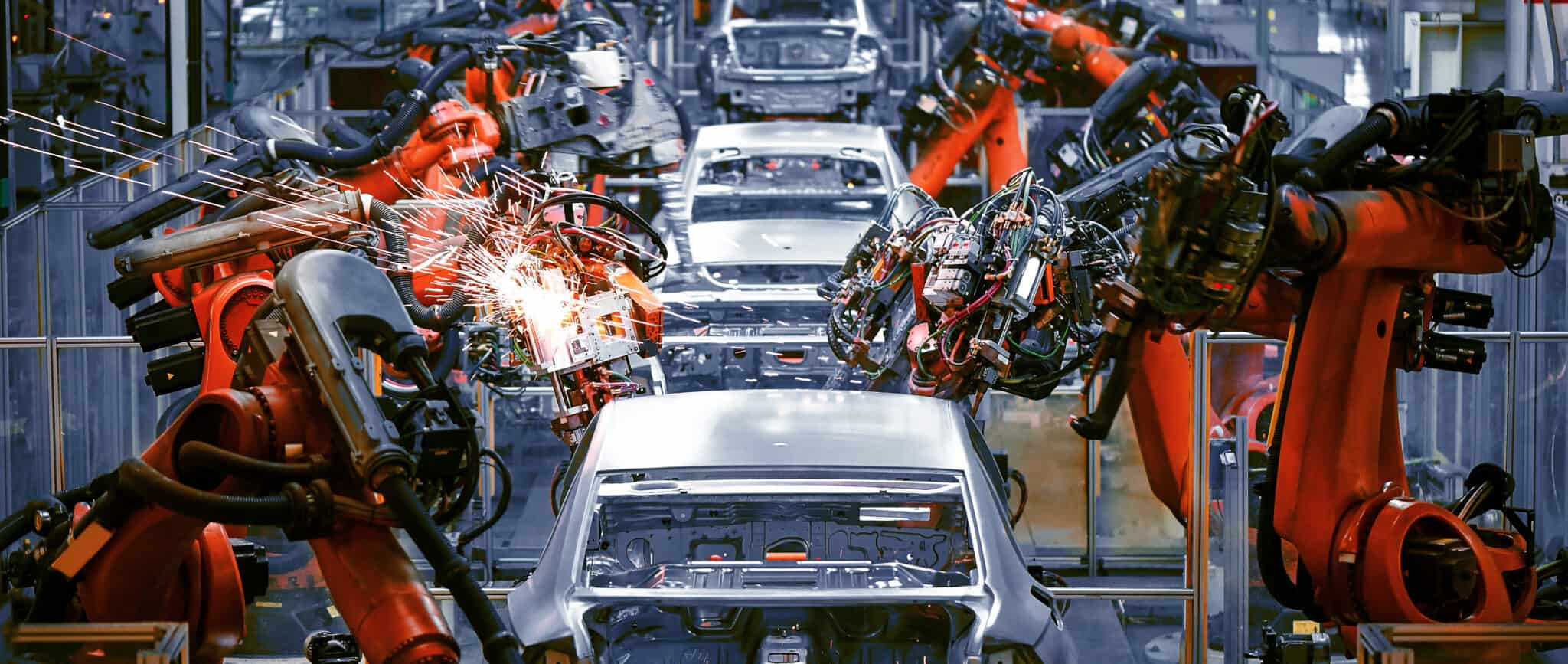

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours