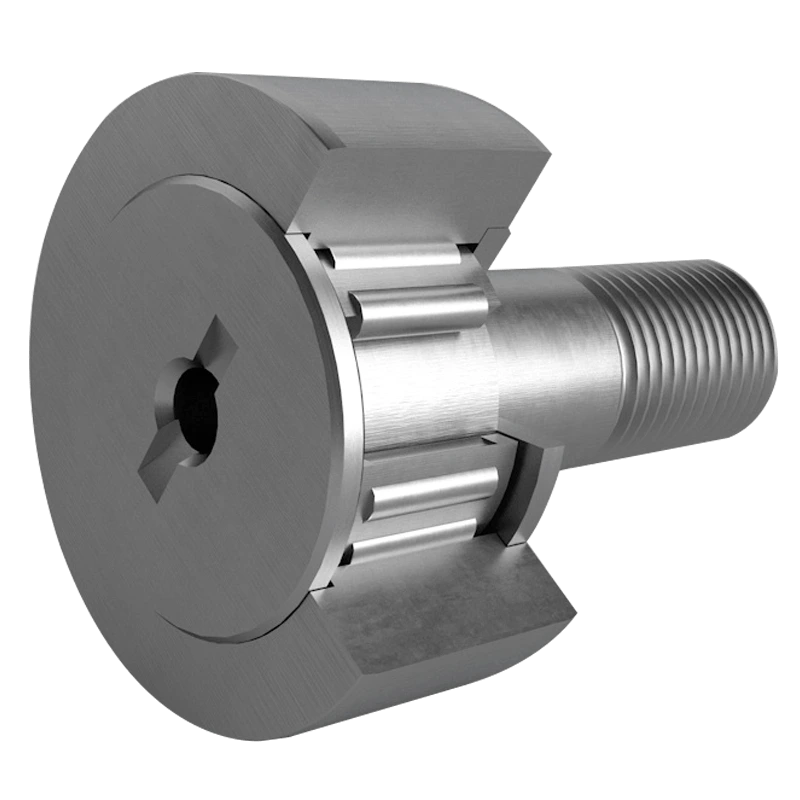

Cam Follower Roller Bearing

Cam follower bearings are heavy-duty rollers for high-load cam and linear motion applications.

Structural Features of Cam Follower Roller Bearings

Integrated Roller and Stud: Combines the track roller with a stud or bolt to provide both radial and axial support with low friction and efficient rotation.

Multi-Component Design: Consists of a stud, track roller, cage, and outer sleeve; the cage keeps rollers evenly spaced for smooth operation.

Sealed Construction: Many models include seals to prevent dust and debris, ensuring long-lasting, stable performance.

Self-Aligning Capability: Can accommodate minor installation misalignments, enhancing assembly flexibility and operational stability.

High Load Capacity: Track rollers made from high-strength steel resist heavy loads and impacts for demanding applications.

Application Environments

Cam Follower Roller Bearings are ideal for applications requiring high load capacity, smooth motion, and durability. Typical environments include:

Heavy Machinery: Cranes, excavators, and material handling equipment benefit from smooth, high-load motion support.

Conveyor Systems: Ensure stable, low-friction operation in high-speed, high-load conveyors, reducing wear and energy loss.

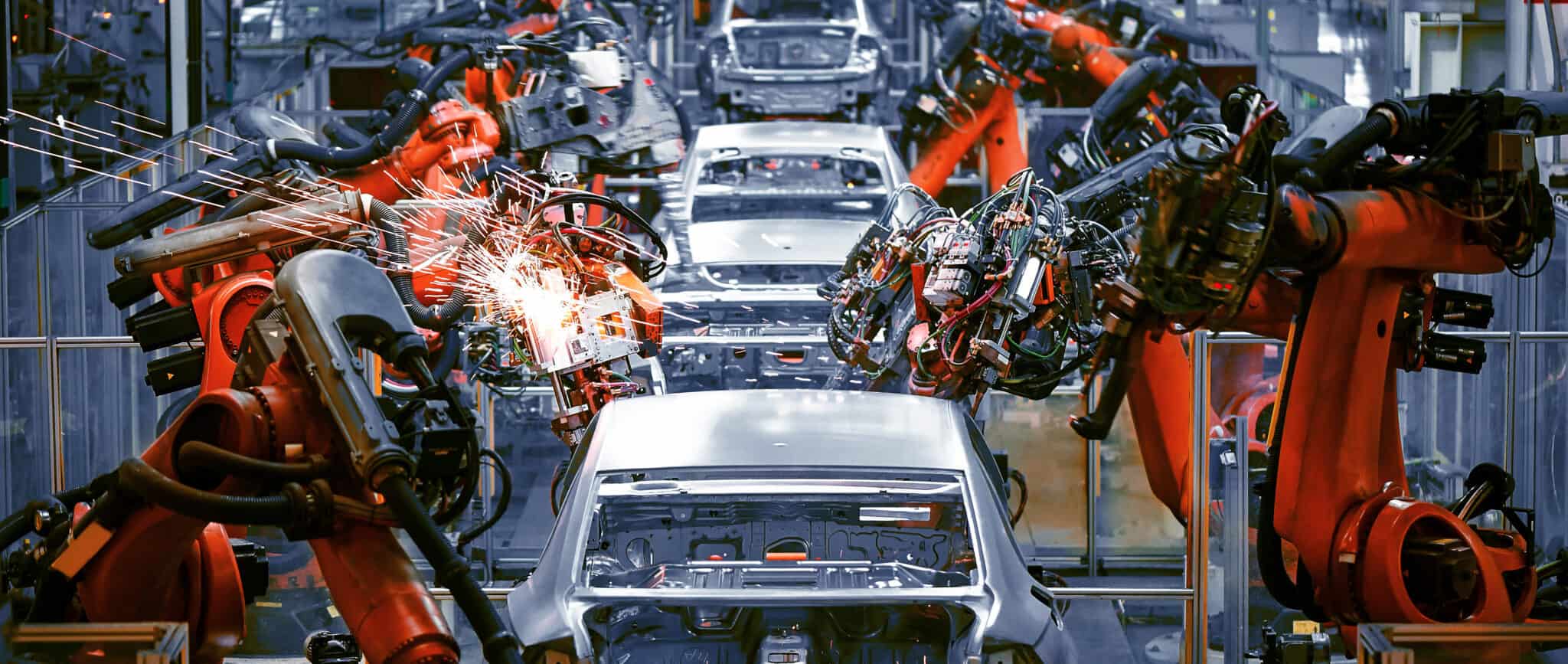

Industrial Automation: Supports precise linear and rotary motion in automated production lines and machinery.

Automotive: Used in suspension, drive systems, and other components requiring high-load motion reliability.

Construction Equipment: Excavators, bulldozers, and other large machinery rely on them to carry heavy loads and reduce friction, prolonging equipment life.

Agricultural Machinery: Tractors, harvesters, and other farming equipment use these bearings in high-load, high-impact environments.

Key Design Features

Integrated Roller and Stud: Combines track roller and bolt for axial and radial support while reducing assembly complexity.

High Load Capacity: Roller elements distribute load efficiently, maintaining stable motion under heavy-duty conditions.

Low Friction & High Efficiency: Compared to sliding supports, rolling elements reduce energy loss and improve operational efficiency.

Wear-Resistant: Large contact area minimizes localized friction, extending bearing life.

Sealed & Dust-Proof: Optional seals prevent dust, debris, and moisture ingress for long-lasting performance.

Self-Aligning: Compensates for minor installation misalignment, enhancing reliability.

Advantages

Heavy-Duty Performance: Can withstand high loads, impacts, and harsh operating conditions.

Extended Service Life: Low friction and wear-resistant design reduce maintenance needs and downtime.

Space-Saving Design: Integrated stud and roller simplify installation and conserve radial space.

Versatile & Adaptable: Performs reliably in high-temperature, humid, or dusty environments.

Precision & Stability: Maintains smooth linear and rotational motion, even under high load conditions.

Leading Global Brands Equivalents

Our Cam Follower Roller Bearings are high-quality alternatives to top brands:

● SKF (Sweden)

● NSK (Japan)

● FAG / INA (Germany)

● Timken (USA)

● RBC Bearings (USA)

● JTEKT (Japan)

● Kitanihon Seiki (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours