Thrust Roller Bearing

Thrust roller bearings support high axial loads with low friction and high rigidity.

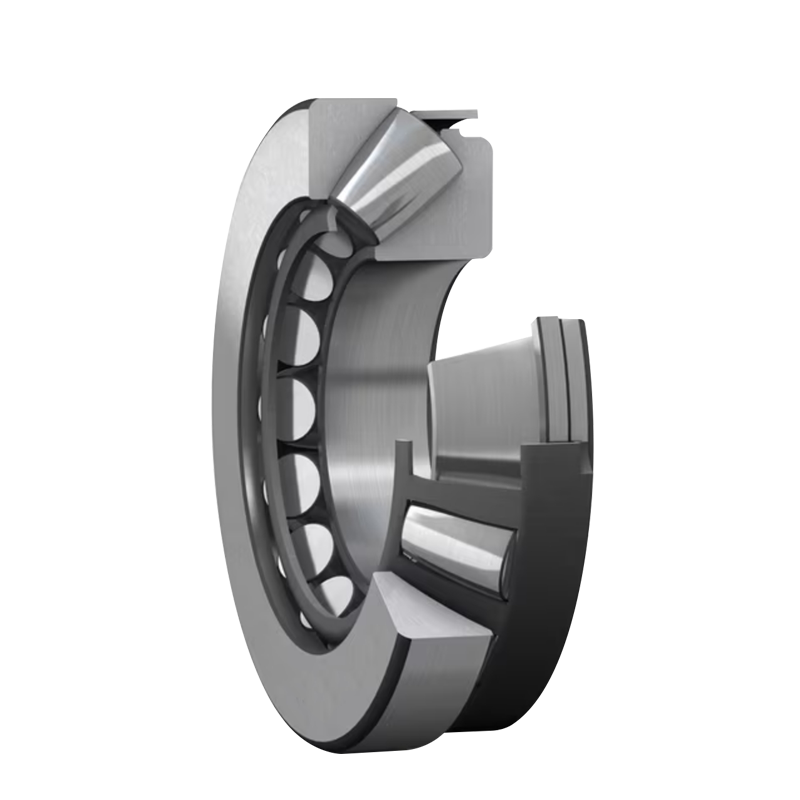

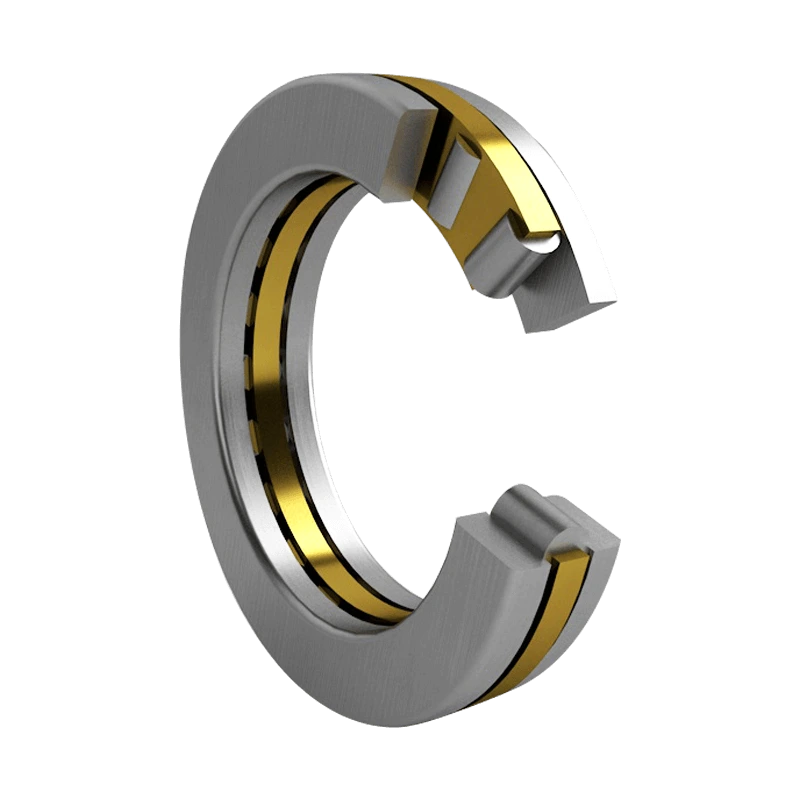

Structural Features of Thrust Roller Bearings

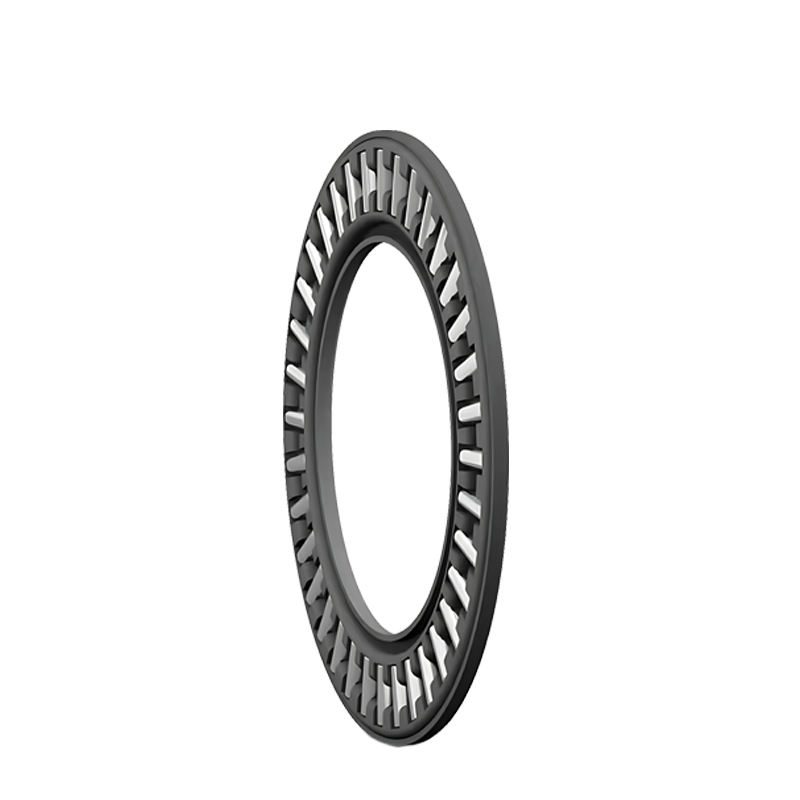

Thrust Cage: Holds rollers in position, ensuring even load distribution and smooth rotation.

Roller Elements: Can be cylindrical, spherical, or needle-shaped, selected based on load type and application requirements.

Washer Design: Consists of two axial rings (washers), one attached to the shaft and the other to the housing, with rollers running between them to support axial loads.

High Axial Load Capacity: Specifically engineered to carry heavy axial loads while minimizing friction; radial load support is limited.

Durable & Stable: Precision design and high-strength materials ensure long service life and reliable operation under heavy-duty conditions.

Low Friction & High Efficiency: Optimized roller arrangement reduces friction, heat generation, and energy loss.

Versatile Applications: Suitable for automotive, industrial machinery, gear drives, and other heavy-duty or precision axial load scenarios.

Structure Type

Application Environments

Thrust roller bearings are ideal for applications requiring high axial load support, smooth rotation, and reliable performance. Typical uses include:

Industrial Machinery: Machine tool spindles, pumps, compressors, and clutches, supporting axial forces at high speeds.

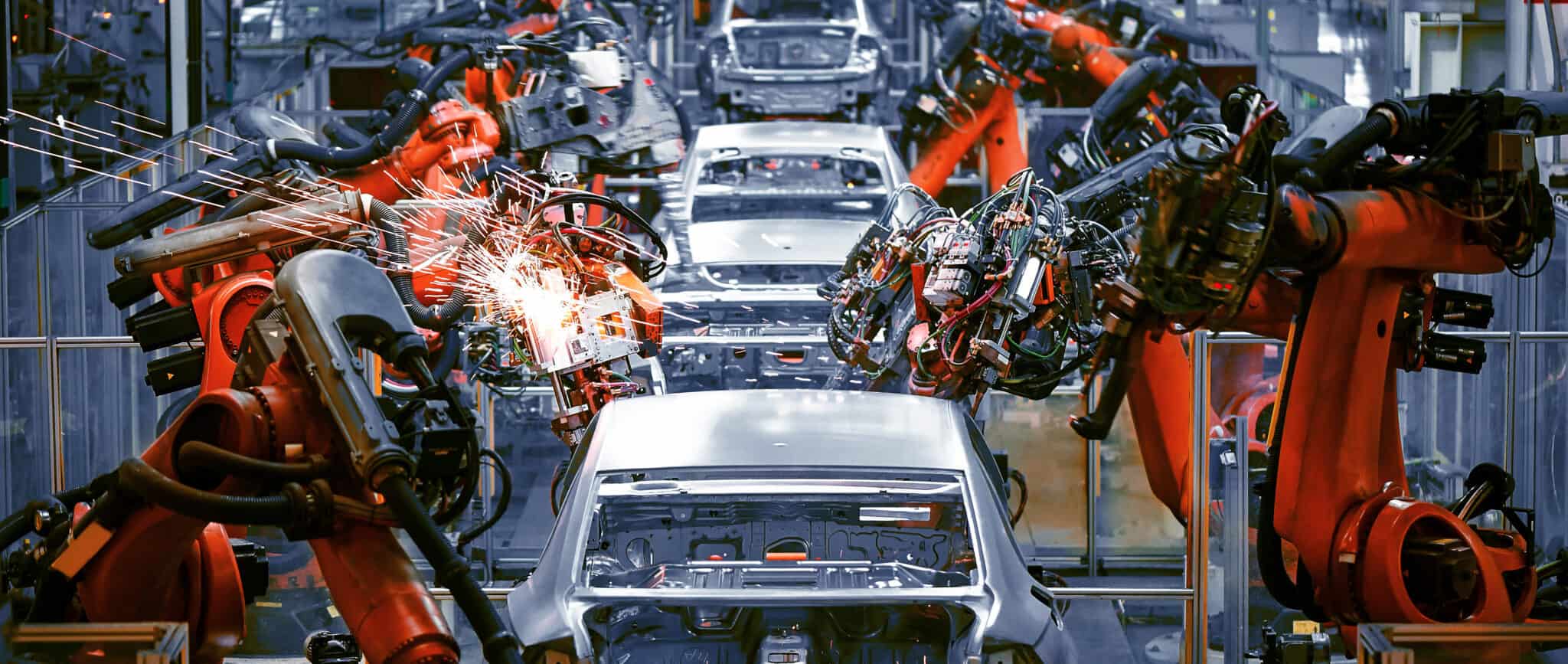

Automotive: Gearboxes, drive shafts, and drivetrains, handling axial thrust during shifting and rotation.

Heavy Machinery: Excavators, cranes, and other construction or mining equipment, supporting large axial loads in rotating platforms and main bearings.

Aviation: Aero engines, turbines, and other high-speed equipment requiring reliable axial load handling.

Key Design Features

High Axial Load Capacity: Engineered to carry heavy axial loads while conserving space.

High-Speed Performance: Optimized for stable, reliable operation under high-speed conditions.

Wear-Resistant Materials: Made from high-strength steel or alloyed materials for durability and long service life.

Versatile Configurations: Available in multiple designs and sizes to suit diverse industrial applications.

Durable & Reliable: Precision manufacturing ensures minimal friction, reduced heat generation, and consistent performance.

Engineering Solutions

Control Axial Displacement: Maintains accurate axial positioning for precise equipment operation.

Support Heavy Loads: Reliable under high-load conditions, reducing maintenance needs and downtime.

Easy Installation & Maintenance: Simplified design facilitates assembly and lubrication.

Adaptable to Harsh Environments: Functions reliably under high temperatures, pressures, and other challenging conditions.

Leading Global Brands Equivalents

Our thrust roller bearings are high-quality alternatives to top global brands:

● SKF (Sweden)

● Timken (USA)

● NSK (Japan)

● FAG (Germany)

● NTN (Japan)

● Schaeffler (Germany)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours