Self-aligning Ball Bearing

Self-aligning ball bearings automatically compensate for misalignment, ensuring smooth, low-friction rotation.

Structural Features of Self-Aligning Bearings

Two Main Types: Available as self-aligning ball bearings with spherical rolling elements or self-aligning roller bearings with cylindrical or barrel-shaped rollers.

High Adaptability: Automatically compensates for shaft misalignment or axis deviations, ensuring reliable operation under imperfect conditions.

Inner Ring Options: Can feature a single inner ring with dual spherical raceways or two separate inner rings, offering greater flexibility and higher load capacity.

Structure Type

Application Environments

Self-aligning ball bearings are ideal for applications with shaft misalignment, variable loads, or structural movement. Common uses include:

Construction Machinery: Tower cranes, overhead cranes, and other heavy equipment where structural movement requires bearing adaptability.

Paper & Textile Machinery: Compensate for shaft deflection during long operating hours, maintaining smooth motion.

Wind Turbines: Handle irregular loads and bent shafts for reliable energy generation.

Mining & Metallurgical Equipment: Bearings cope with heavy loads on unstable foundations, reducing maintenance and improving operational efficiency.

Key Design Features

Automatic Alignment: Compensates for misalignment from shaft bending or mounting errors.

Versatile Load Support: Handles high radial loads and moderate axial loads efficiently.

Reduced Friction & Wear: Self-aligning design minimizes internal friction, extending service life.

Maintenance-Friendly: Reduces installation complexity and the need for frequent adjustments.

Engineering Solutions

Correct Alignment Errors: Automatically adapts to installation or operational misalignments.

Stable Under Complex Loads: Maintains reliable performance under variable or multi-directional loads.

Simplified Installation: Self-centering function enables faster, easier assembly without high-precision skills.

Lower Maintenance Costs: Reduces breakdowns and downtime, improving overall equipment efficiency.

Leading Global Brands Equivalents

Our self-aligning bearings are high-quality alternatives to top brands:

● SKF (Sweden)

● NSK (Japan)

● FAG (Germany)

● NTN (Japan)

● Timken (USA)

● Schaeffler (Germany)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

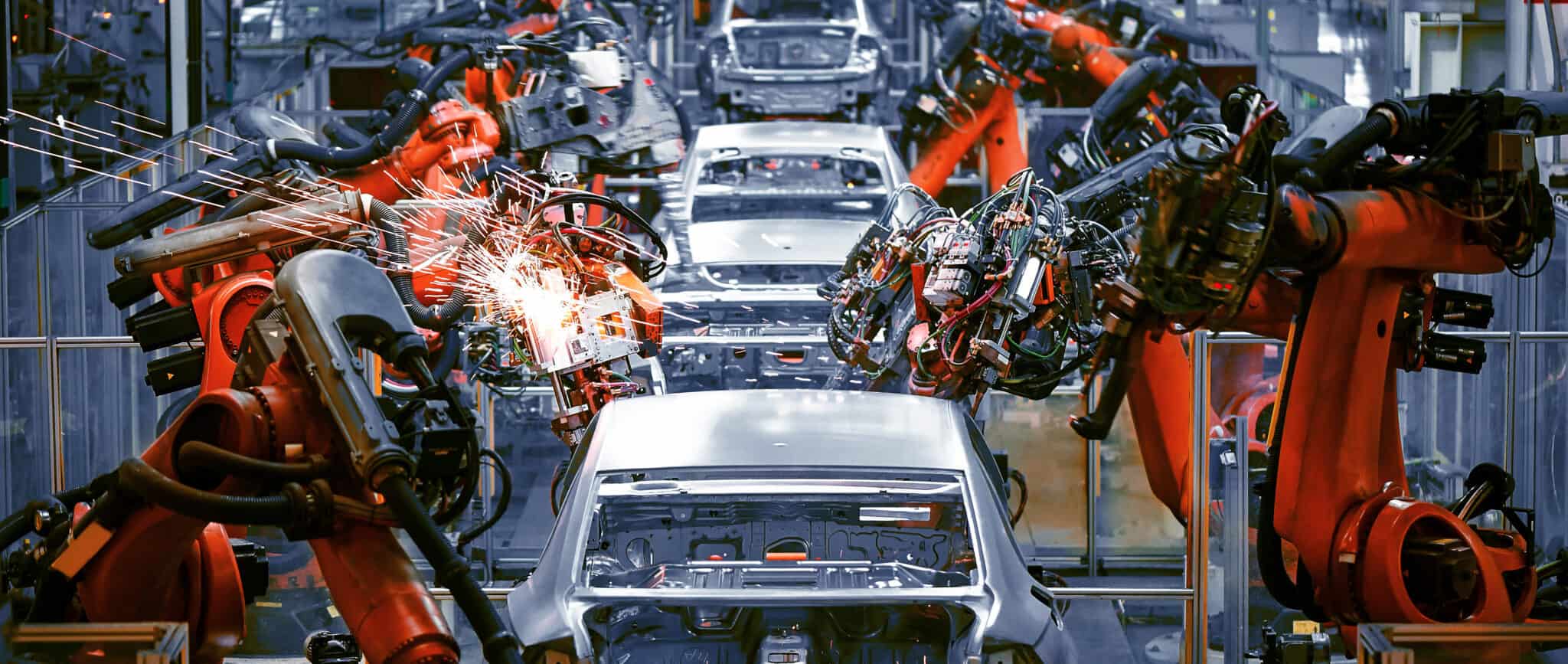

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours