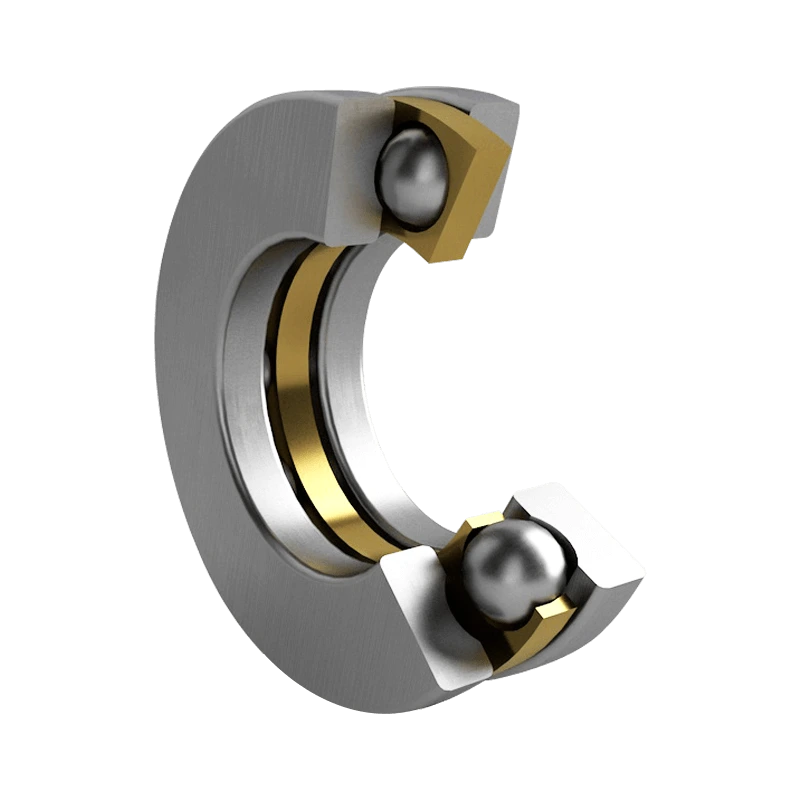

Thrust Ball Bearing

Thrust ball bearings support axial loads with smooth, low-friction rotation.

Structural Features of Thrust Ball Bearings

Ball Rolling Elements: Use spherical balls running in precision raceways to support axial loads with low friction.

Washer Assembly: Composed of a shaft washer and a housing washer, with rolling elements positioned between them.

Cage Design: Maintains proper ball spacing and alignment for smooth and stable operation.

One-Way & Two-Way Types: Available to support axial loads in one direction or in both directions, depending on application requirements.

Structure Type

Application Environments

Thrust ball bearings are widely used in applications where axial load support and smooth rotation are required. Typical applications include:

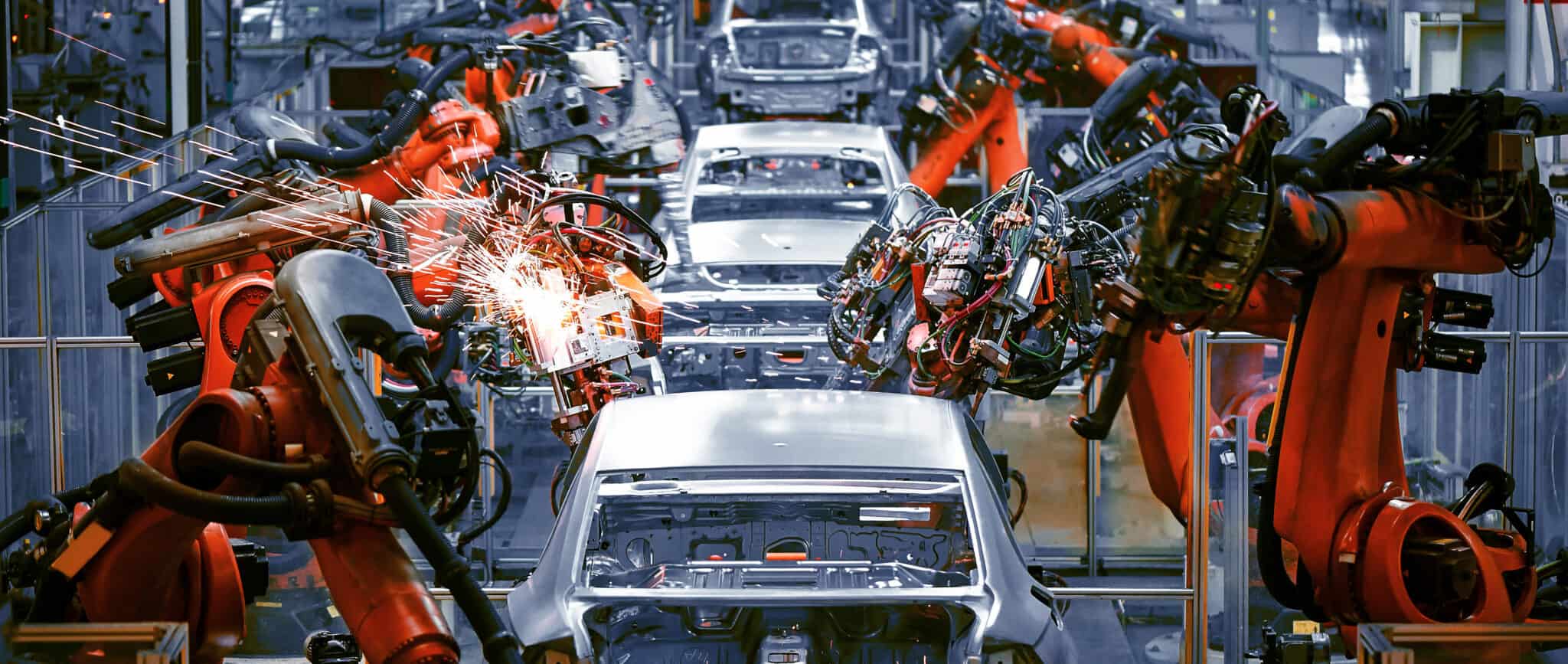

Automotive Industry: Commonly used in clutches and transmission systems to withstand axial forces generated during gear shifting and operation.

Aerospace & Aviation: Applied in aircraft landing gear, control systems, and servo mechanisms to maintain accurate positioning under axial loads.

Industrial Machinery: Used in pumps, fans, compressors, and gear systems to support axial loads and ensure stable, efficient operation.

Household Appliances: Found in washing machines and similar rotating equipment, handling axial loads generated by rotating drums and shafts.

General Mechanical Equipment: Suitable for light-to-medium duty axial load applications across various industries.

Key Design Features

High Axial Load Capacity: Designed specifically to handle axial loads efficiently despite a simple structure.

Compact Structure: Space-saving design allows easy integration into equipment with limited installation space.

Low Friction & Smooth Operation: Optimized raceway and ball arrangement reduce friction, heat generation, and energy loss.

One-Way & Two-Way Options: Available for axial load support in one direction or both directions to suit different application needs.

Reliable & Cost-Effective: Simple construction ensures dependable performance with economical manufacturing and maintenance costs.

Engineering Solutions We Provide

Control Axial Displacement: Effectively manages axial movement to maintain accurate alignment and stable operation.

Solve Space Limitations: Compact design enables reliable axial load support in tight installation environments.

Improve System Reliability: Protects other components by properly absorbing axial forces, extending overall system life.

Easy Installation & Maintenance: Simple design reduces installation time and maintenance complexity.

Leading Global Brand Equivalents

Our thrust ball bearings are high-quality alternatives to the following well-known brands:

● SKF (Sweden)

● FAG (Germany)

● NSK (Japan)

● Timken (USA)

● NTN (Japan)

● Koyo (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours