Angular Contact Ball Bearing

Designed to handle both radial loads and axial loads, providing reliable performance for industrial applications.

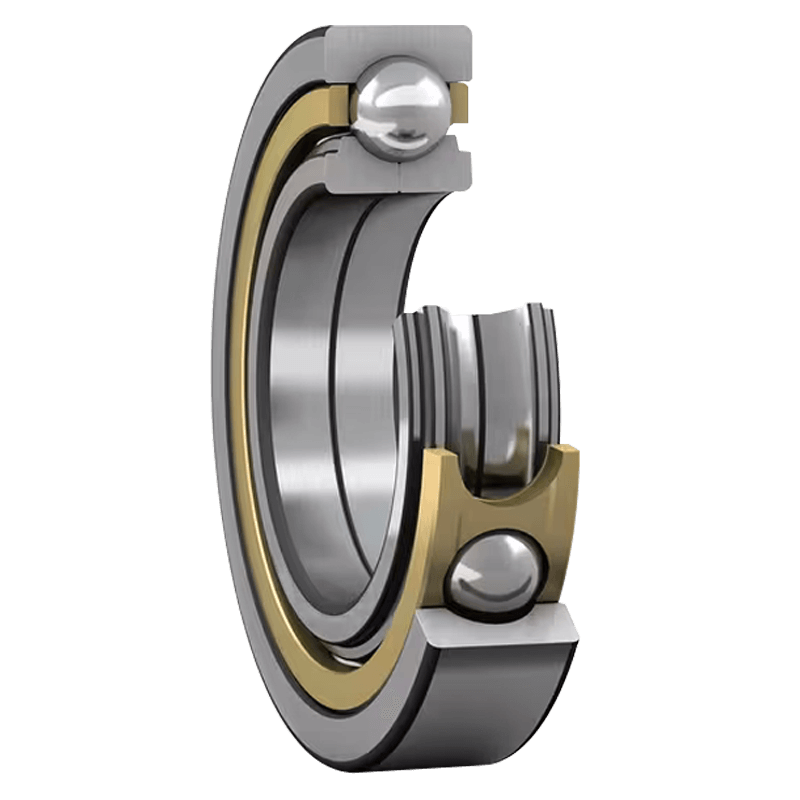

Contact Angle: Angular contact ball bearings feature a contact angle between the inner and outer rings (typically 15°–40°). A larger angle increases axial load capacity.

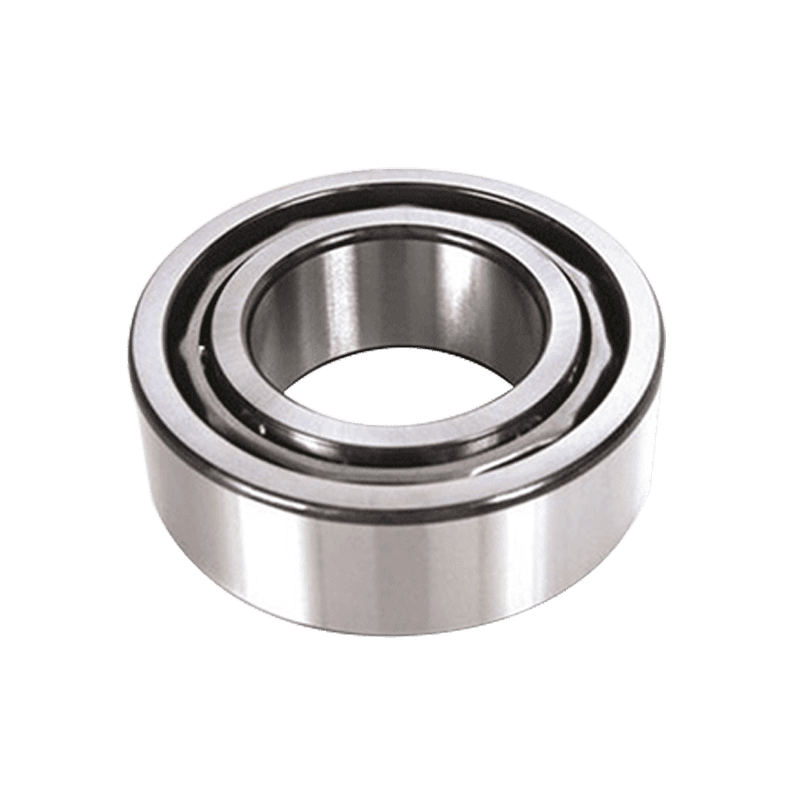

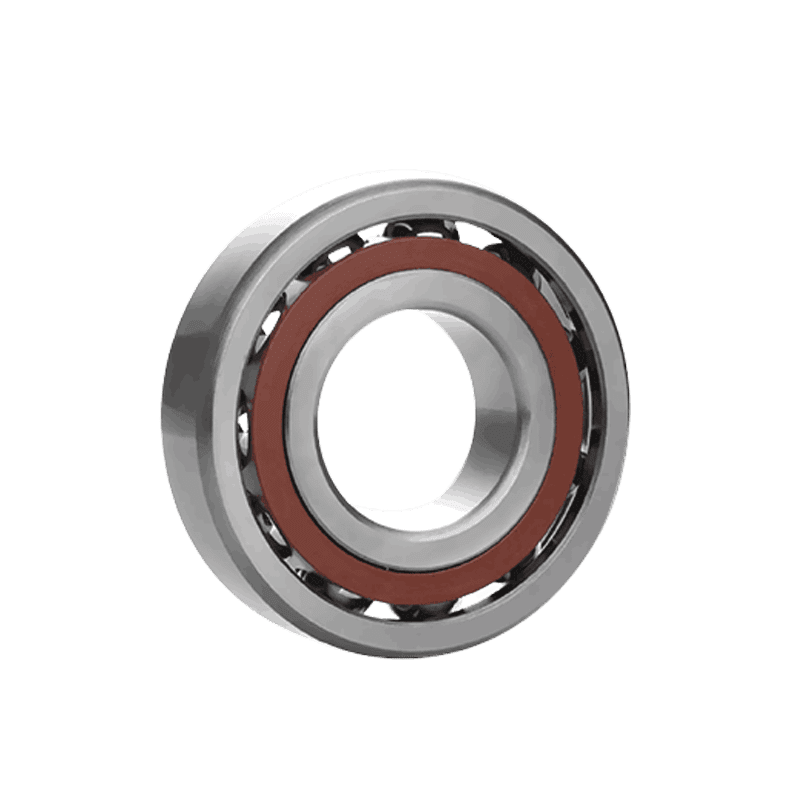

Single and Double Rows: Available in single-row designs for unidirectional axial loads, and double-row designs for bidirectional axial loads.

Ball & Groove Design: The curved raceway and ball contact surface increase the contact area, enhancing load capacity and extending service life.

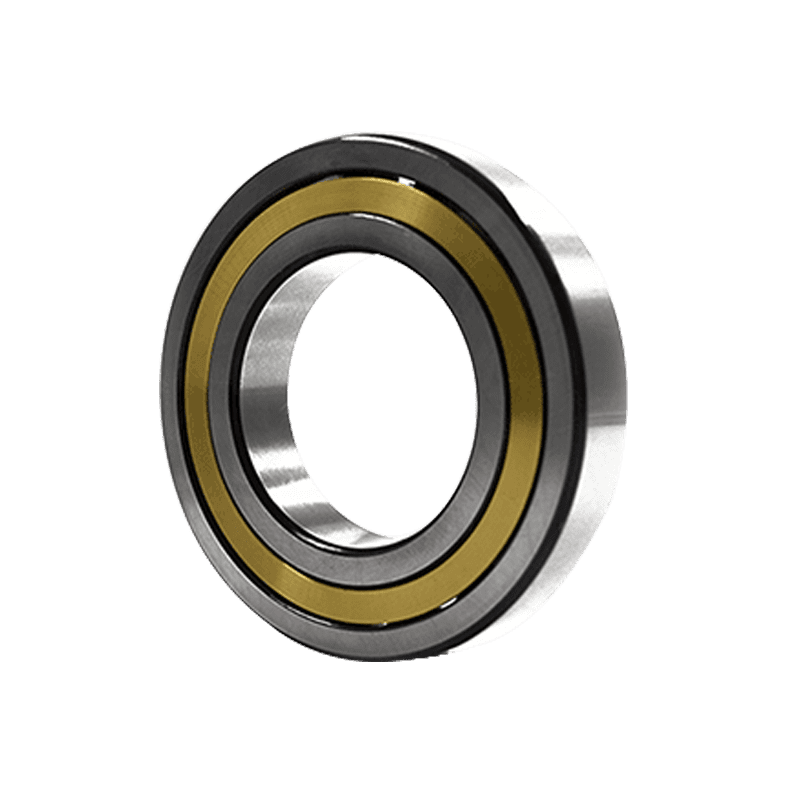

Structure Type

Application Environment

Precision Instruments: Ideal for CNC machine tools and other equipment requiring high accuracy and stable operation.

Automotive Components: Commonly used in steering and transmission systems to support and transfer loads efficiently.

Aerospace: Suitable for high-speed, variable-load environments, ensuring stable and reliable performance.

Agricultural & Construction Machinery: Capable of handling heavy loads and shock loads in tractors, loaders, and other rugged equipment.

Design Features

High-Speed Performance: Optimized structures reduce friction and heat generation for high-speed applications.

High Precision: Manufactured to tight tolerances, making them suitable for demanding, high-accuracy applications.

Load Adaptability: Various contact angle designs support different combinations of axial and radial loads.

Multiple Sealing Options: Available in open, sealed, or shielded types to suit different working environments and maintenance needs.

Engineering Solutions

Improve Operational Efficiency: Reduced internal friction enhances machine performance and energy efficiency.

Handle Complex Loads: Proper selection of contact angle and design supports combined axial and radial loads.

Enhance System Rigidity: Improves rigidity in high-speed, high-precision equipment.

Longer Service Life: Robust materials and precision manufacturing ensure reliable performance in harsh conditions.

Equivalent to Leading International Brands

SKF (Sweden)

NSK (Japan)

FAG (Germany)

NTN (Japan)

Timken (USA)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

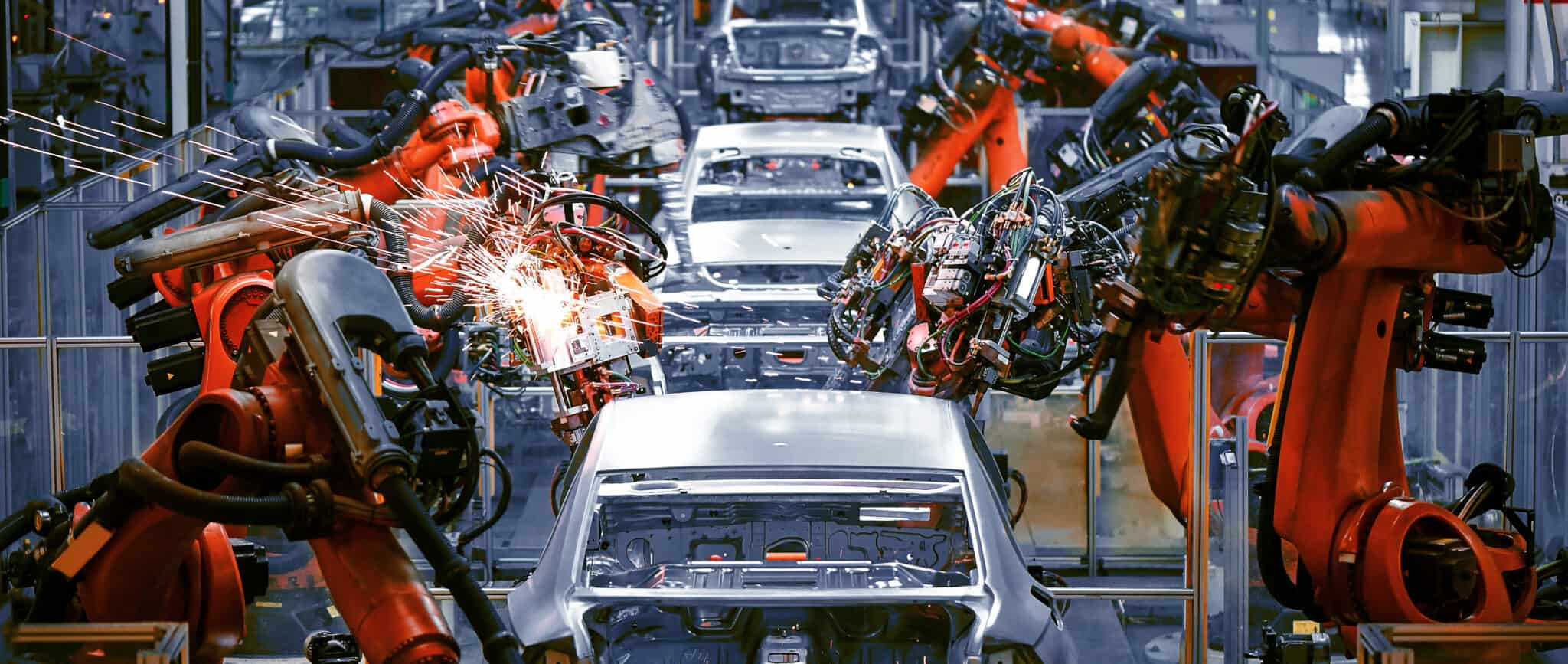

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours