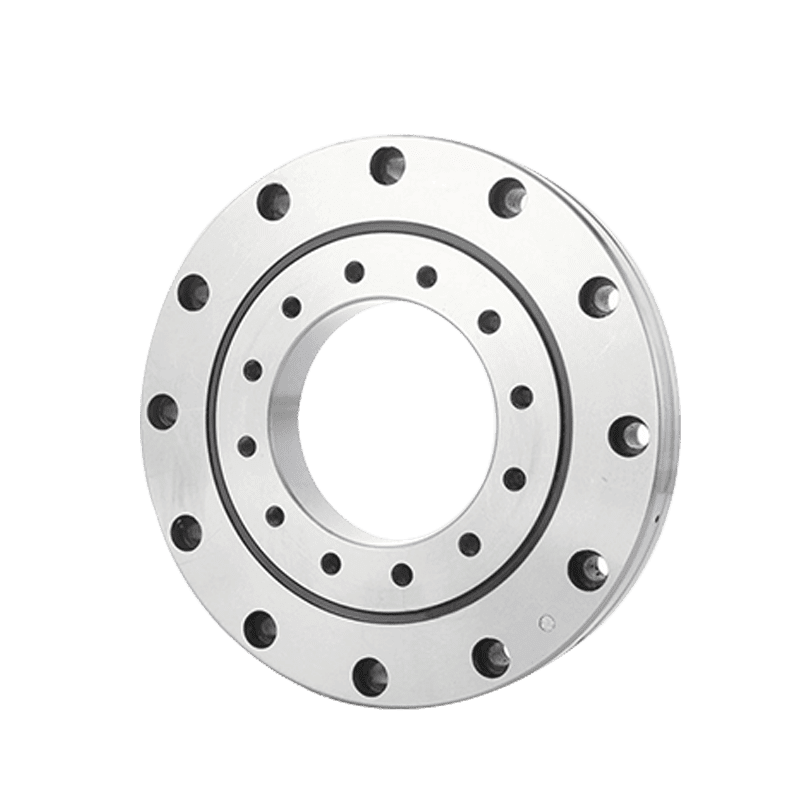

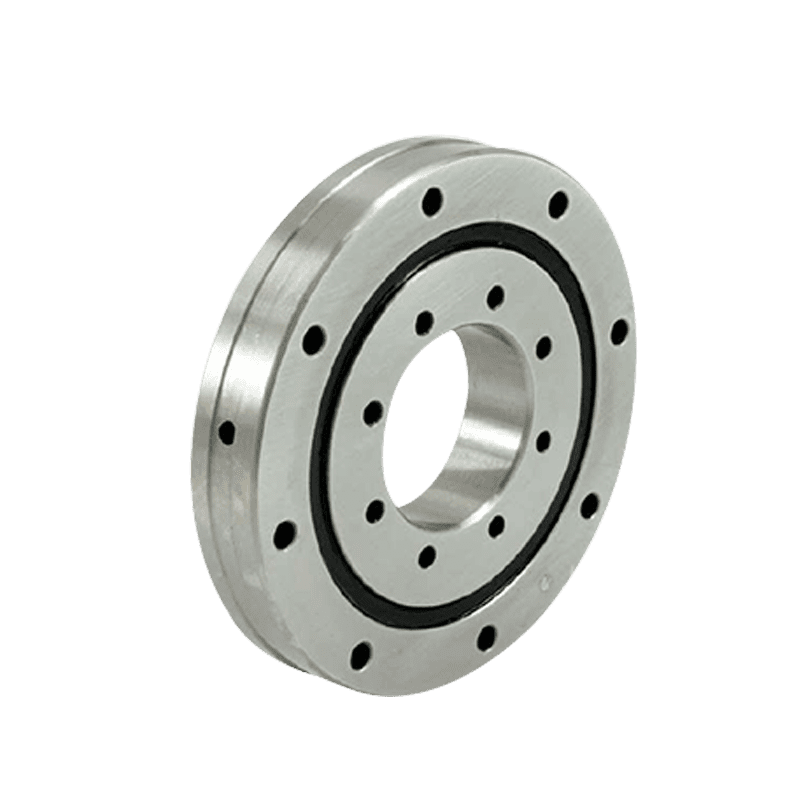

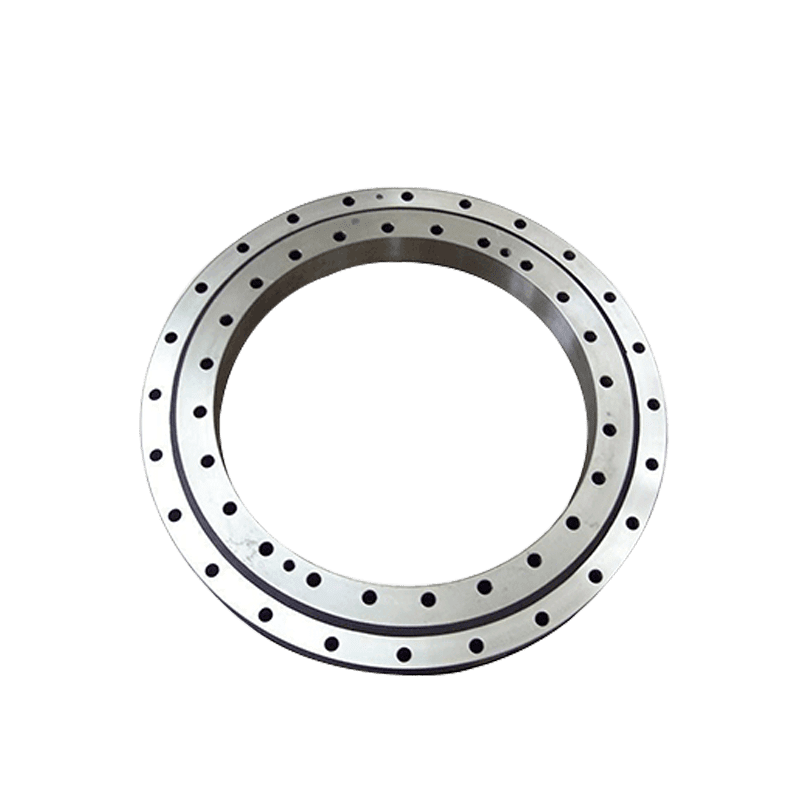

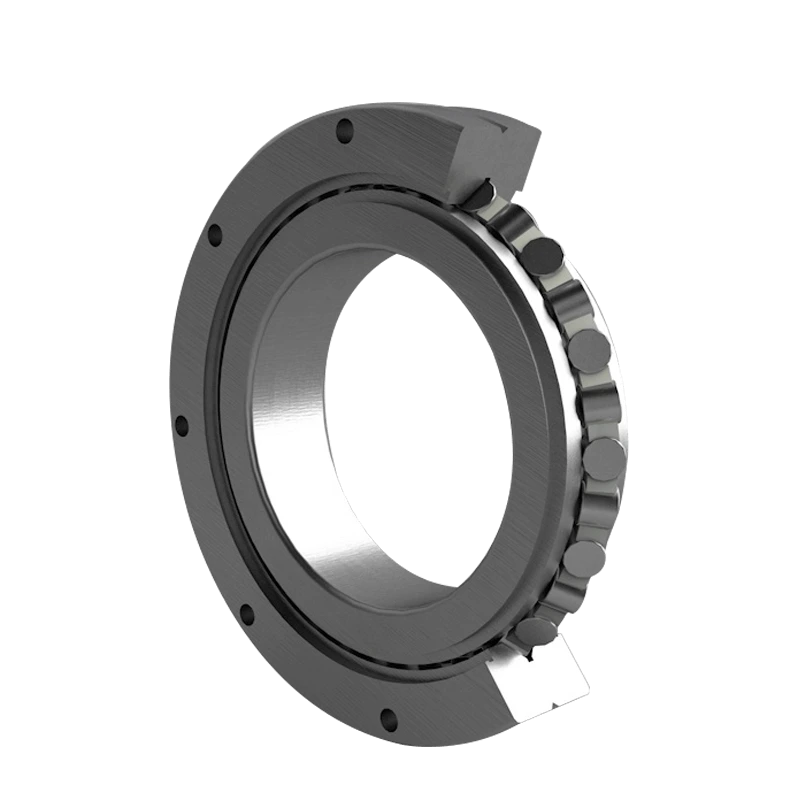

Crossed Roller Bearing

Staggered rollers for high precision and heavy loads.

Structural Features

Cross-Aligned Rollers: Staggered rollers carry loads from all directions simultaneously.

Single-Bearing Construction: Combines multiple functions in one bearing, saving space and simplifying design.

High Precision: Manufactured to tight tolerances for accurate motion control.

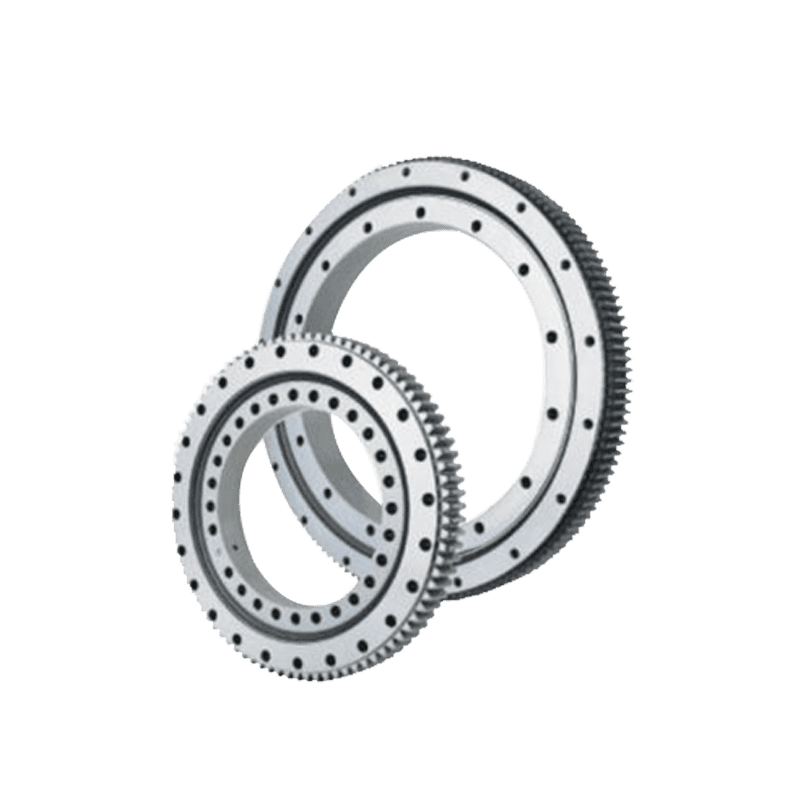

Split Rings: Some bearings feature split inner and outer rings for easier installation and maintenance.

Structure Type

Application Environment

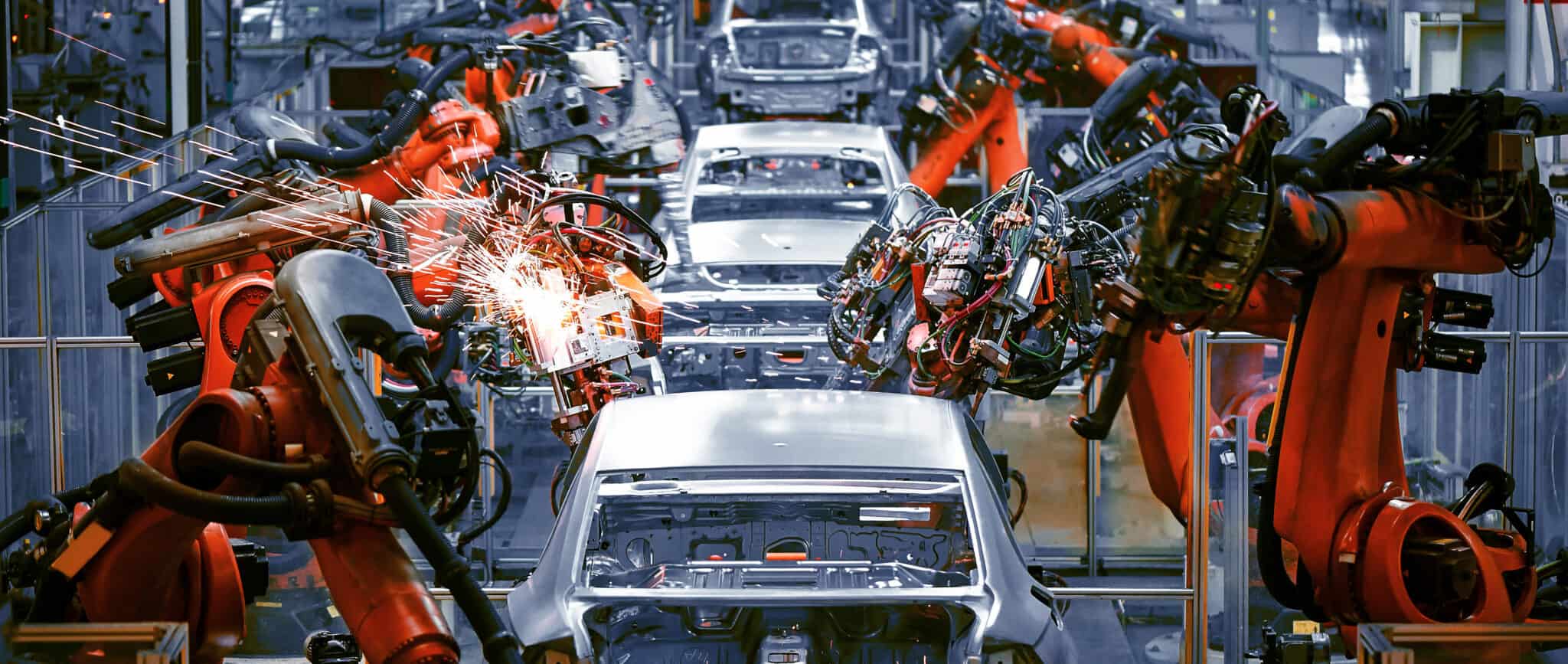

Robotics: Ideal for robot joints and rotating parts due to high rigidity and compact design.

Rotary & Reference Tables: Used in precision machine tool tables requiring high accuracy and load capacity.

Medical Devices: Suitable for high-speed, precision components such as CT machine rotating parts.

Aerospace & Aeronautics: Applied in critical spacecraft and aircraft components for high reliability and rigidity.

Design Features

High Load Capacity: Crossed rollers provide strong radial and axial load support in a compact space.

High Rigidity: Roller arrangement minimizes deformation and deflection.

High Precision: Low clearance and friction ensure accurate rotary motion.

Compact Design: Delivers high performance while saving space.

Engineering Solutions

Space Constraints: Optimized for compact or space-limited applications.

Load Handling: Supports complex, multi-directional, or heavy-duty loads.

Motion Accuracy: Enhances precision and responsiveness of motion systems.

Ease of Installation & Maintenance: Split design simplifies assembly, maintenance, and reduces downtime.

Equivalent to Leading International Brands

THK (Japan)

IKO (Japan)

INA (Germany)

NSK (Japan)

Timken (USA)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours