Deep Groove Ball Bearing

Reliable, High-Precision Bearings for Industrial Applications

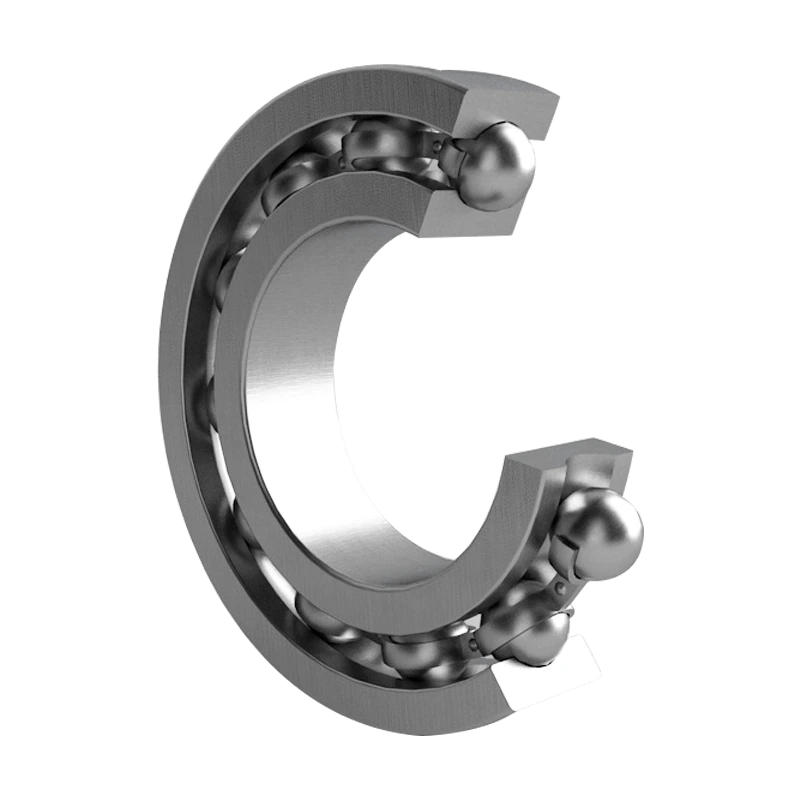

Structural Features

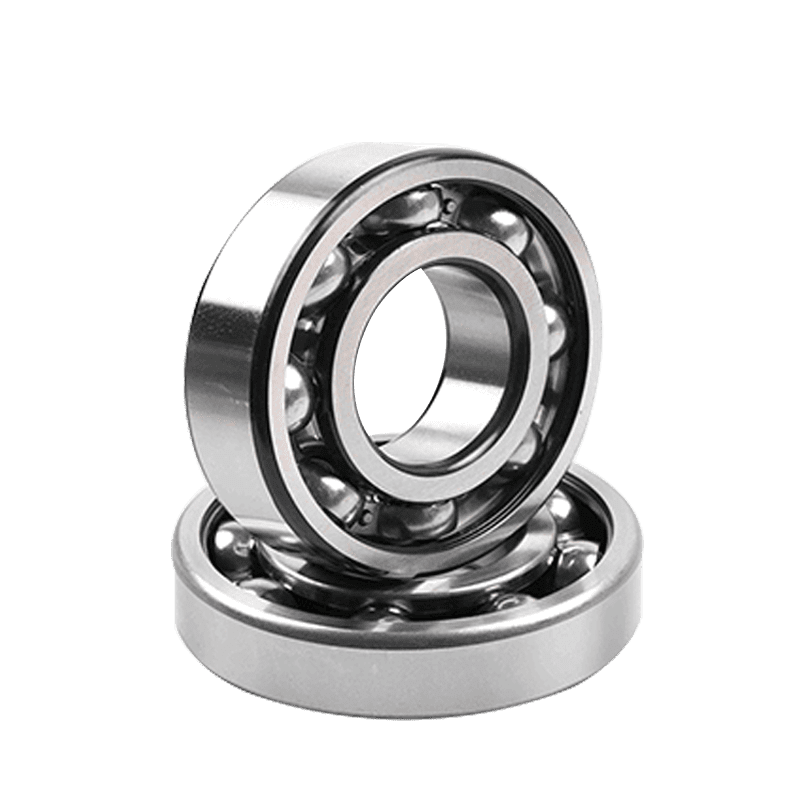

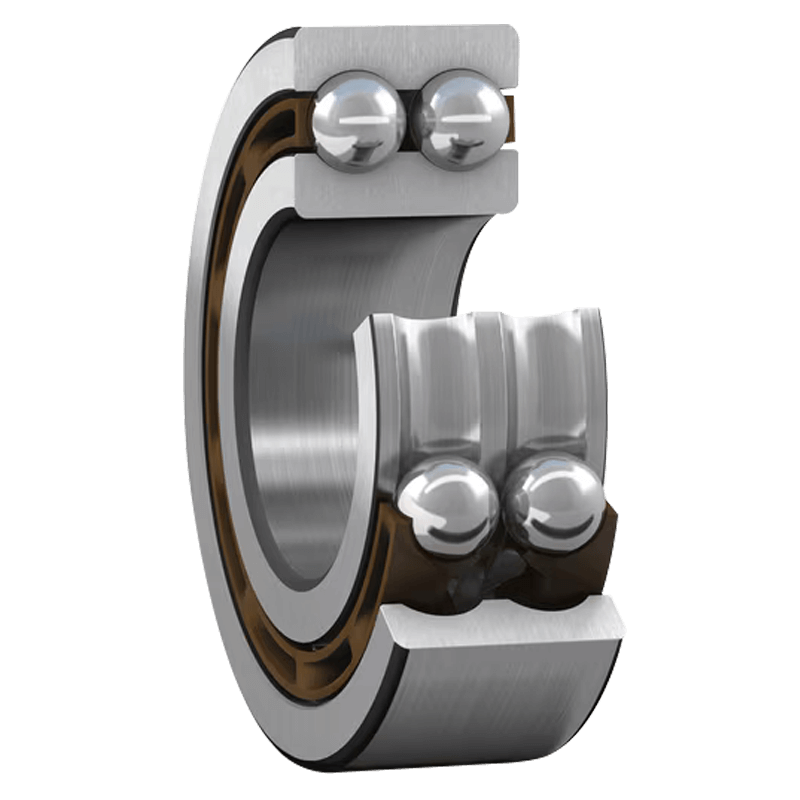

Single and Double Row Designs: Deep groove ball bearings are available in single-row and double-row configurations. Single-row bearings are ideal for standard load applications, while double-row designs offer higher load-carrying capacity and enhanced rigidity.

Raceway Depth: The inner and outer rings feature deep raceways, increasing radial load capacity and ensuring reliable performance under demanding conditions.

Ball Spacing: Steel balls are evenly separated by a precision cage, maintaining uniform distribution, reducing friction, and improving bearing stability and efficiency.

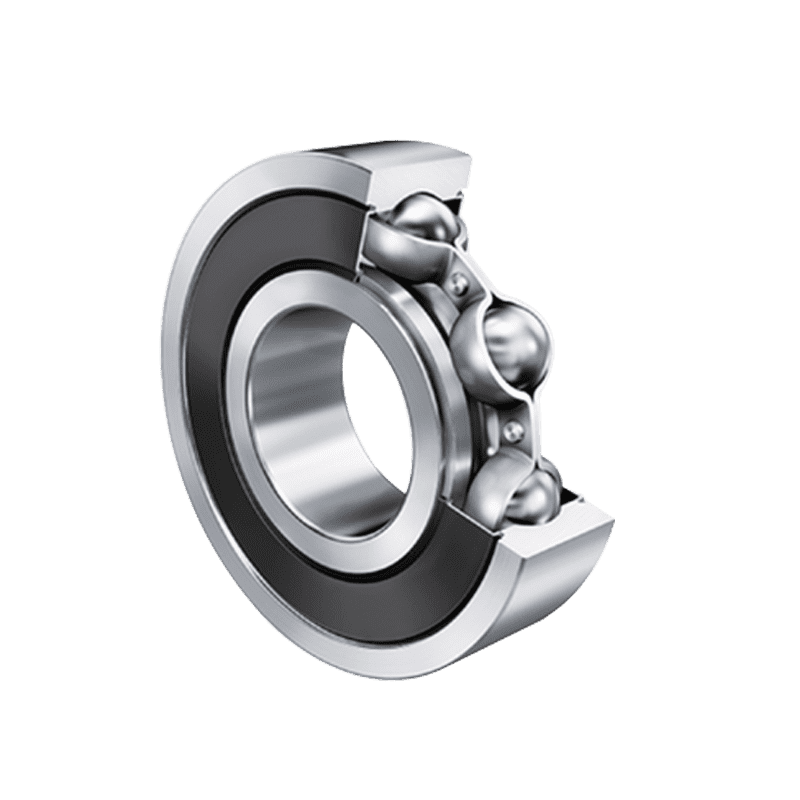

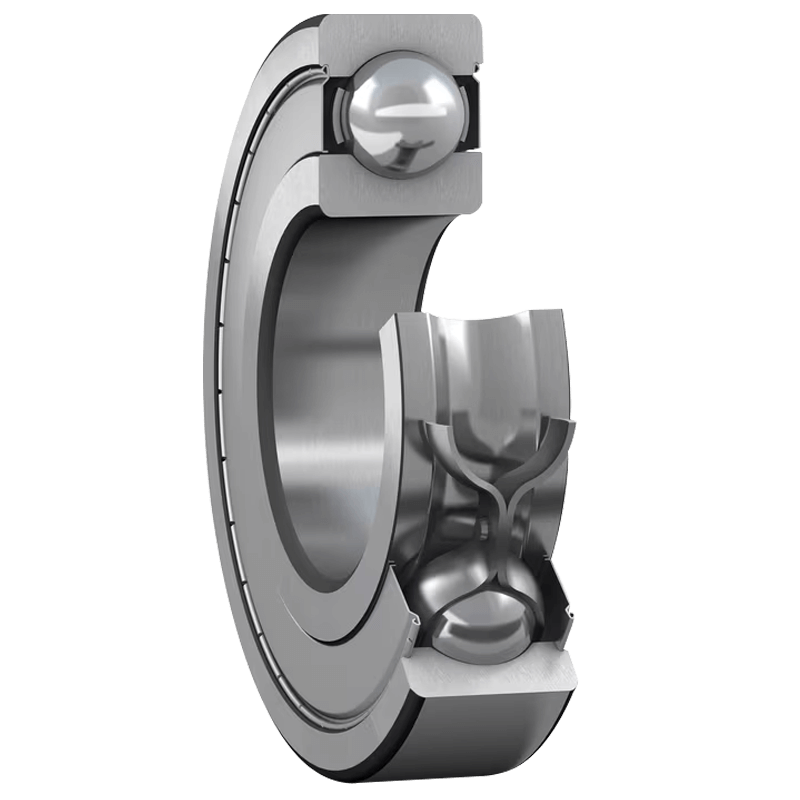

Sealing and Shielding Options: Bearings can be equipped with various seals or shields—such as rubber seals or metal shields—tailored to the specific application to protect against contaminants and extend service life.

Structure Type

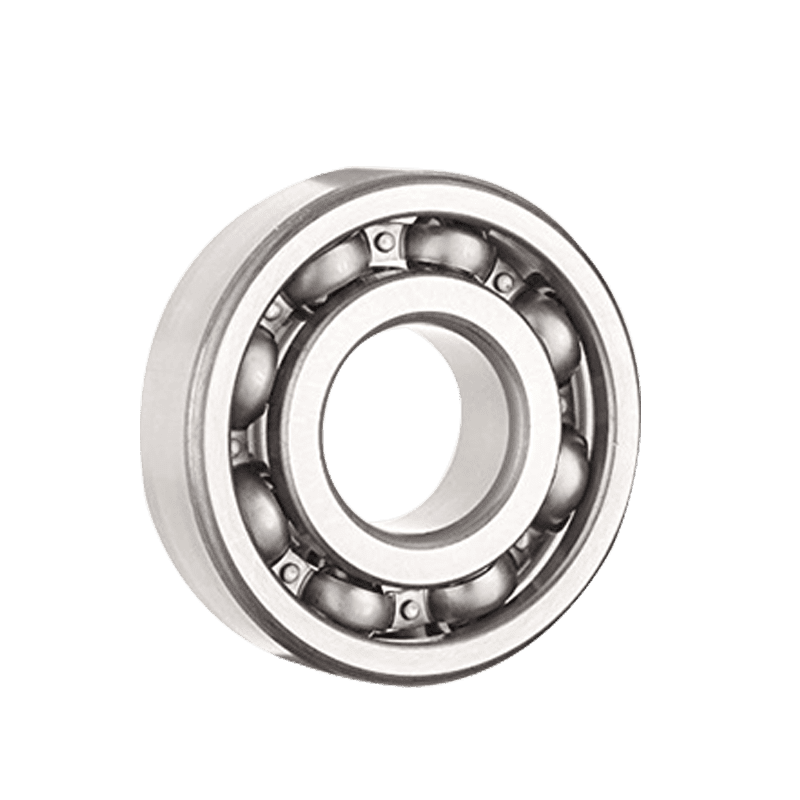

Stainless Steel Deep Groove Ball Bearing

Application Environment

High-Speed Applications: Ideal for fast-rotating components in electric motors, household appliances, and power tools.

High-Load Applications: Suitable for drive systems in industrial machinery and automotive equipment, capable of handling heavy radial and axial loads.

Precision Instruments: Perfect for devices requiring high accuracy, minimal vibration, and low noise operation.

Outdoor and Harsh Environments: Reliable performance in agricultural machinery, construction equipment, and other applications exposed to dust, moisture, and challenging conditions.

Design Features

High Load-Bearing Capacity: Deep groove design allows bearings to withstand substantial radial and axial forces.

Durability: Manufactured from premium steel with precision engineering, ensuring long service life even in demanding conditions.

Self-Lubricating Options: Certain bearings feature self-lubrication, reducing maintenance frequency and improving operational efficiency.

Versatile Sealing Solutions: Multiple sealing configurations available to meet dust-proof, waterproof, and harsh-environment requirements.

Engineering Solutions to Your Challenges

Lower Maintenance Costs: High-quality, long-life bearings minimize downtime and reduce replacement frequency.

Enhanced Efficiency: Optimized designs improve mechanical performance and reduce energy consumption.

Adaptability to Harsh Conditions: Special seals and materials enable reliable operation in extreme or corrosive environments.

Noise and Vibration Reduction: Advanced engineering minimizes operational noise and vibration, improving user experience.

Equivalent to Leading International Brands

SKF (Sweden)

NSK (Japan)

FAG (Germany)

NTN (Japan)

Timken (USA)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

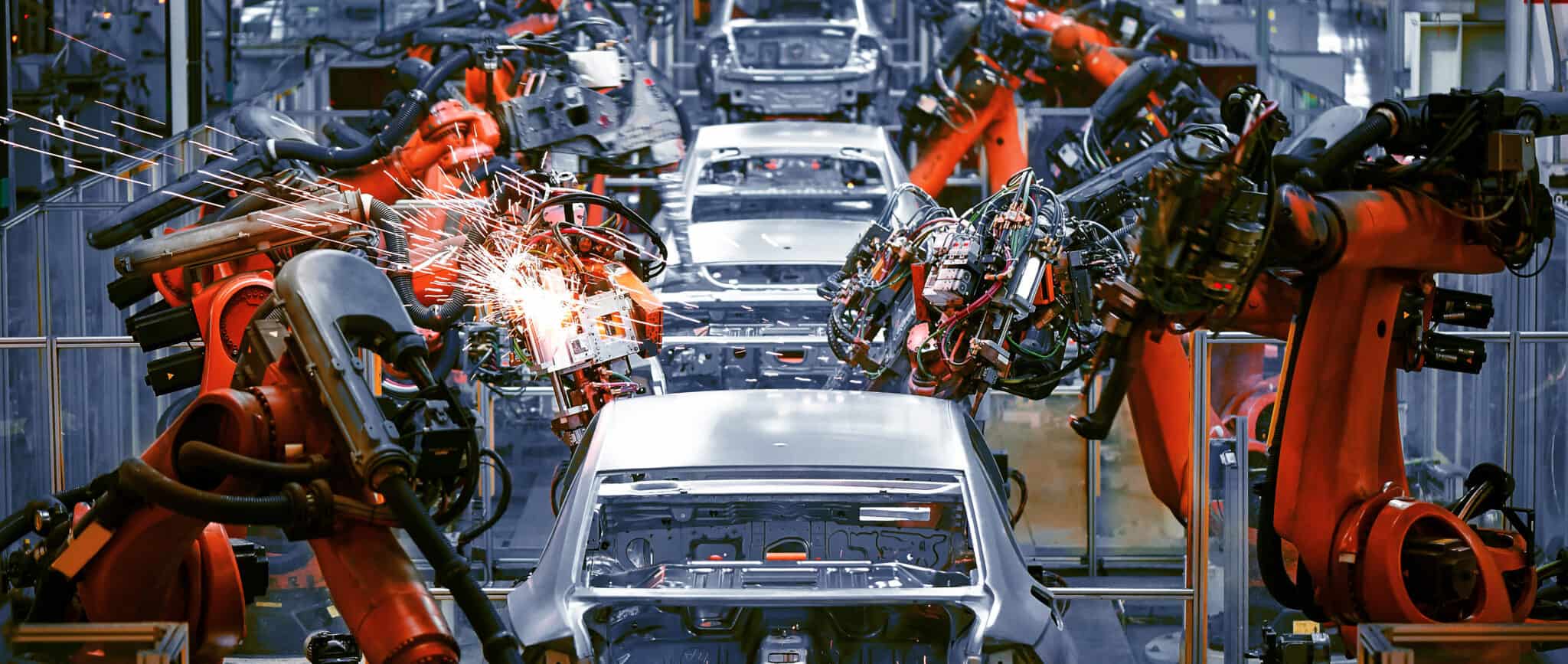

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours