Linear Guideway Bearings

Linear guideway bearings provide precise, smooth, high-load linear motion in compact designs.

Structural Features of Linear Guide Bearings

Guide Rail: The foundation of the system, made from high-strength steel or advanced materials to provide smooth sliding and reliable support.

Slide Block: The moving component housing rolling elements, ensuring low-friction motion and high load capacity along the rail.

Rolling Elements: Balls or rollers that roll between the rail and block, carrying loads efficiently while minimizing friction.

Seals & Dust Covers: Protect the bearing from dust and debris, maintaining smooth performance and extending service life.

Lubrication System: Integrated lubrication reduces friction, wear, and ensures long-term durability.

Structure Type

Application Environments

Linear guideway bearings are ideal for applications requiring high-precision, smooth linear motion, including:

CNC Machines: Ensure accurate spindle and workpiece movement in lathes, milling, and grinding machines.

Industrial Robots: Provide precise, smooth motion for robotic arms and automated manipulators.

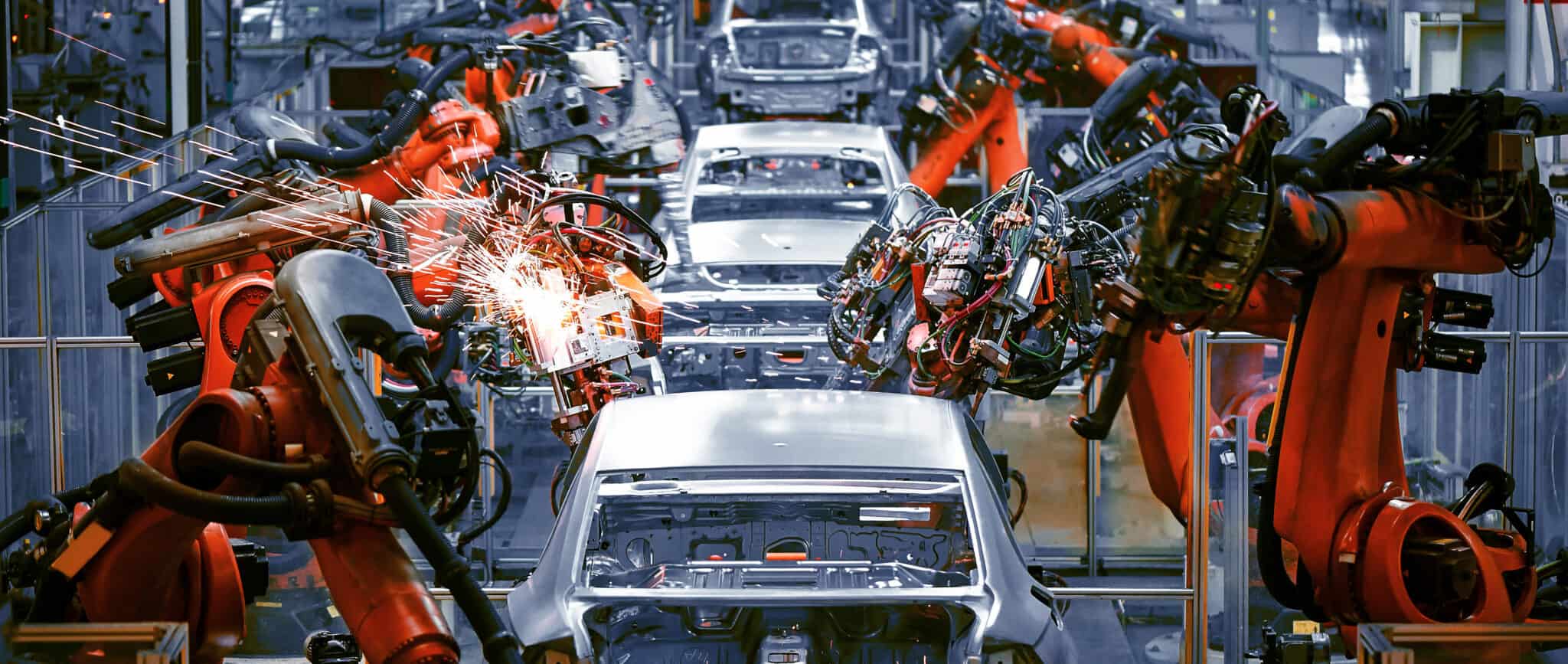

Automated Production Lines: Support high-precision motion in assembly, inspection, and handling systems.

Measuring Equipment: Used in CMMs, laser systems, and other devices demanding ultra-accurate positioning.

Medical Equipment: Enable precise motion in imaging, testing, and automation devices.

Packaging & Conveying Systems: Ensure smooth handling and transport in high-speed production lines.

Key Design Features

Low Friction & High Load Capacity: Rolling elements reduce friction, increase load support, and extend service life.

High Precision & Rigidity: Maintains stable, accurate motion even under heavy loads.

Easy Installation & Maintenance: Standardized sizes simplify assembly and lubrication; some models feature self-lubrication.

Adaptable & Durable: Resistant to dust, moisture, corrosion, temperature changes, and harsh environments.

Quiet & Smooth Operation: Reduces vibration and noise compared to sliding guides.

Advantages

Precise, stable linear motion for high-end machinery.

Low friction and wear reduce energy consumption and maintenance.

High load capacity and rigidity ensure reliable performance under heavy-duty conditions.

Adaptable to harsh environments with dust-proof, waterproof, and corrosion-resistant features.

Smooth, quiet operation enhances efficiency and workplace comfort.

Leading Global Brands

● THK (Japan)

● HIWIN (Taiwan)

● NSK (Japan)

● SKF (Sweden)

● FAG (Germany)

● IKO (Japan)

● Schneeberger (Switzerland)

● Rollon (Italy)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours