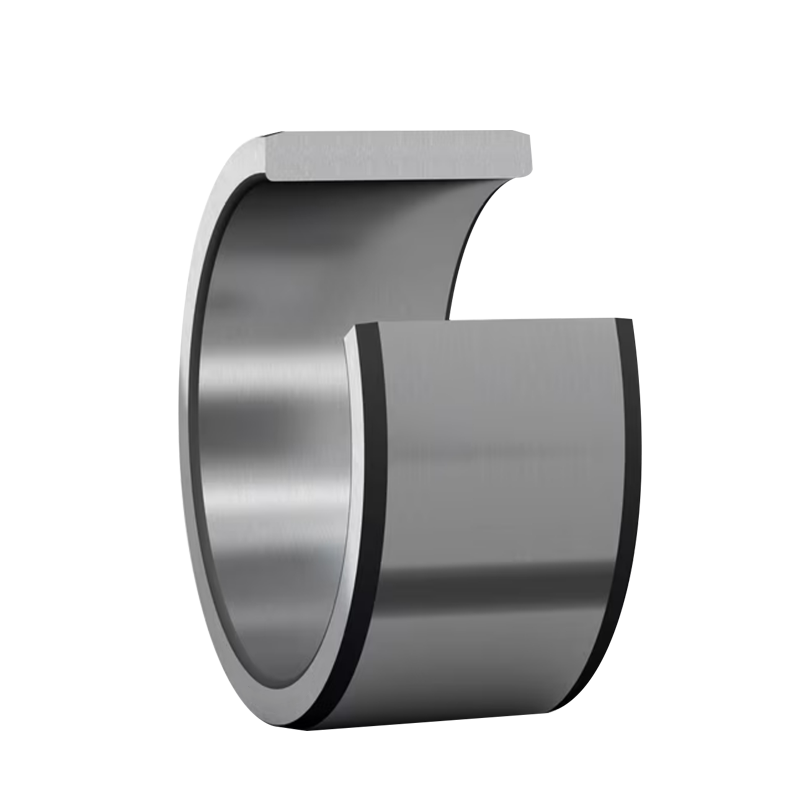

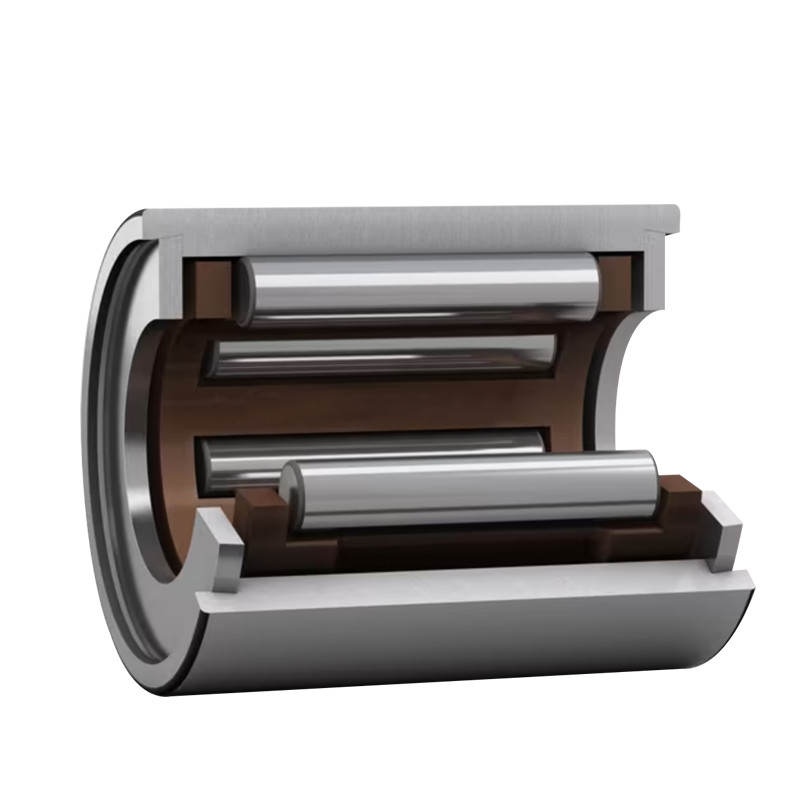

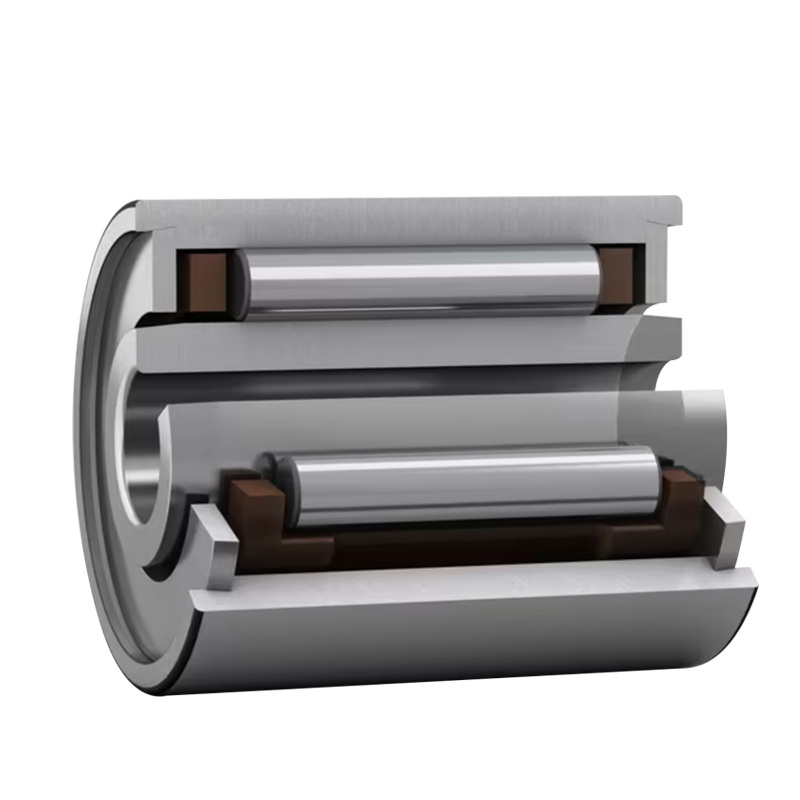

Needle Roller Bearing

Needle roller bearings are compact, high-load bearings with long, thin rollers for limited-space applications.

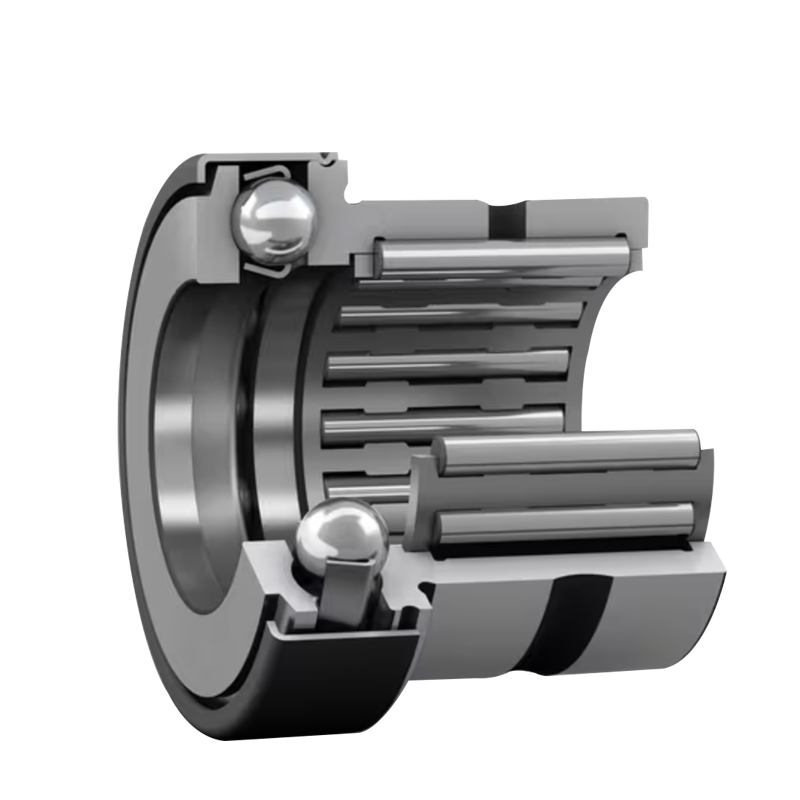

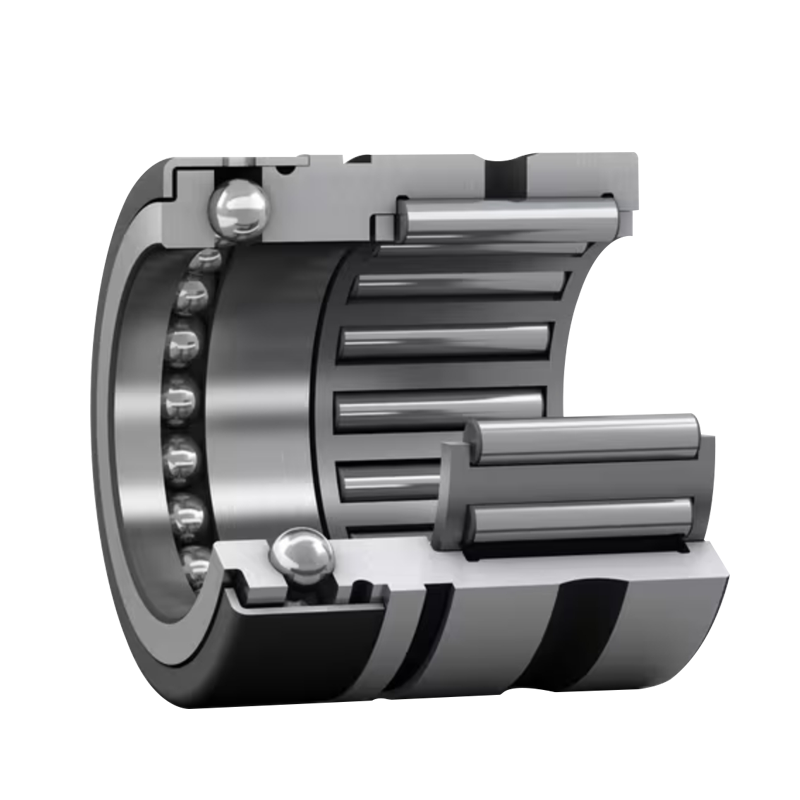

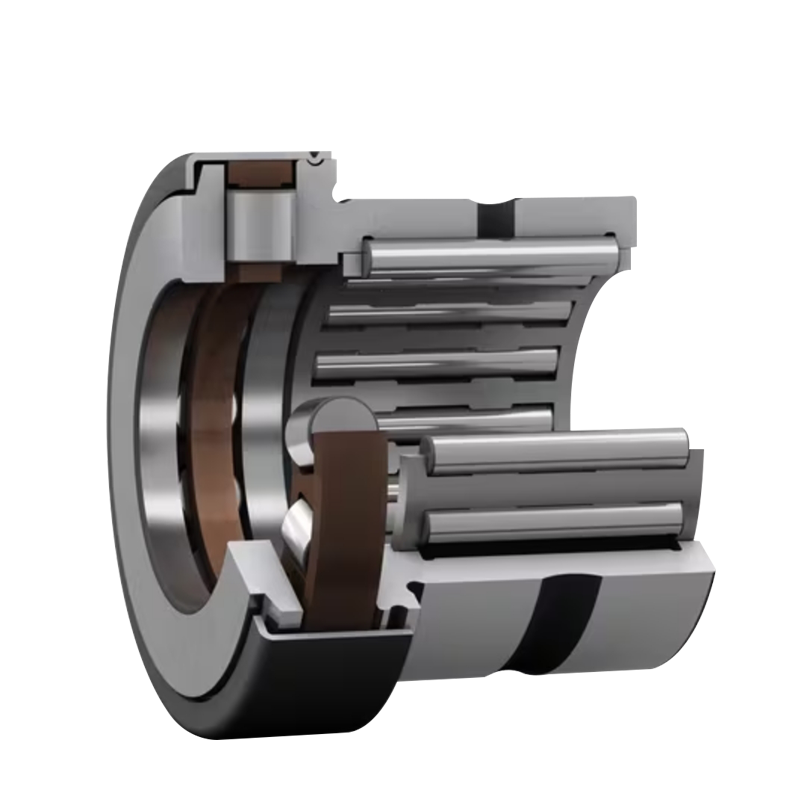

Structural Features

Needle-Like Rollers: Long, slender rollers maximize contact area while keeping the bearing compact.

High Load Capacity: Multiple needle rollers share the load, enabling high radial load support despite small bearing size.

Flexible Design: Can be used with or without an inner ring; the shaft itself can serve as a raceway for space-saving applications.

Caged or Non-Caged Options: Cages keep rollers evenly spaced, prevent skewing, and enhance operational stability.

Durable & Reliable: Precision manufacturing and high-strength materials ensure long service life even under heavy loads.

Compact & Lightweight: Ideal for applications where space is limited and weight reduction is important.

Versatile Applications: Suitable for automotive components, industrial machinery, robotics, and other high-precision equipment.

Structure Type

Alignment Needle Roller Bearings with An Inner Ring

Application Areas

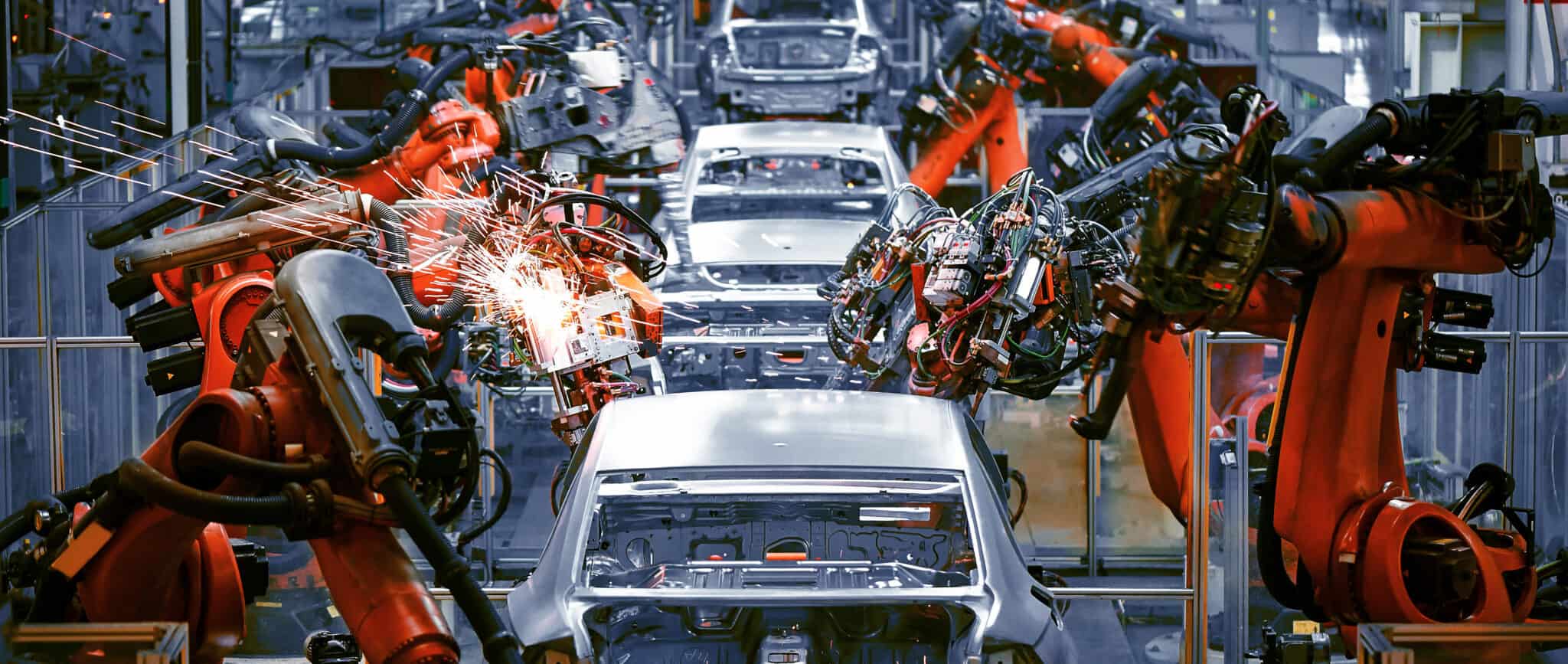

Automotive: Ideal for engine connecting rods, gearboxes, differentials, and other components requiring compact, high-load bearings.

Industrial Machinery: Used in textile, printing, and various transmission systems where precision and load capacity are critical.

Agricultural Equipment: Supports gear drives, conveyors, and other heavy-duty components with durability and high load tolerance.

Aerospace & Defense: Suitable for high-load, high-pressure applications in aircraft, satellites, and defense machinery requiring reliable performance.

Robotics & Automation: Compact design and high load capacity make them perfect for precision actuators and automated systems.

Design Advantages

Compact & Space-Saving: Slim profile fits tight radial spaces without compromising performance.

Flexible Installation: Available with or without inner rings, adaptable to different mounting configurations.

High Efficiency: Low friction design maintains smooth motion while supporting heavy radial loads.

Durable & Reliable: Precision manufacturing and high-strength materials ensure long service life under demanding conditions.

Customizable Sealing & Lubrication: Various options available to suit different environments, from dust-proof to high-speed applications.

Engineering Solutions We Provide

Solve Space Limitations: Perfect for compact machines without sacrificing load capacity.

Handle Heavy Loads: Designed for applications requiring high rigidity under radial constraints.

Enhance Longevity: Bearings maintain performance and reliability even in harsh operating conditions.

Cost-Effective Performance: High durability with minimal maintenance reduces total lifecycle costs.

Tailored Solutions: Custom sizes, materials, and sealing options available to meet specific application needs.

Brand Equivalents

Our needle roller bearings are high-quality alternatives to top global brands:

● SKF (Sweden)

● INA / Schaeffler (Germany)

● Timken (USA)

● NSK (Japan)

● NTN (Japan)

● Koyo (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours