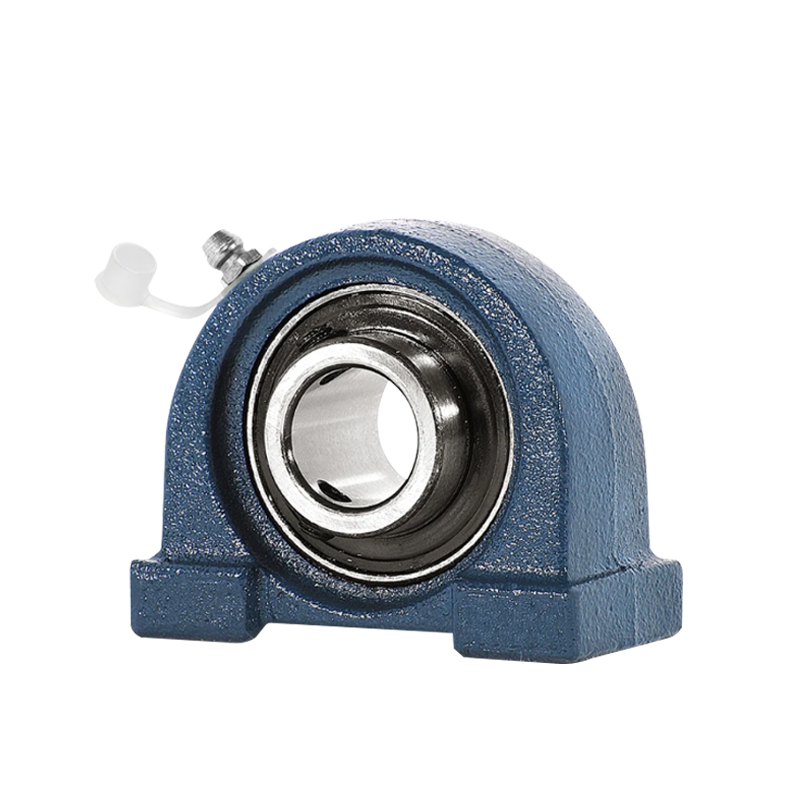

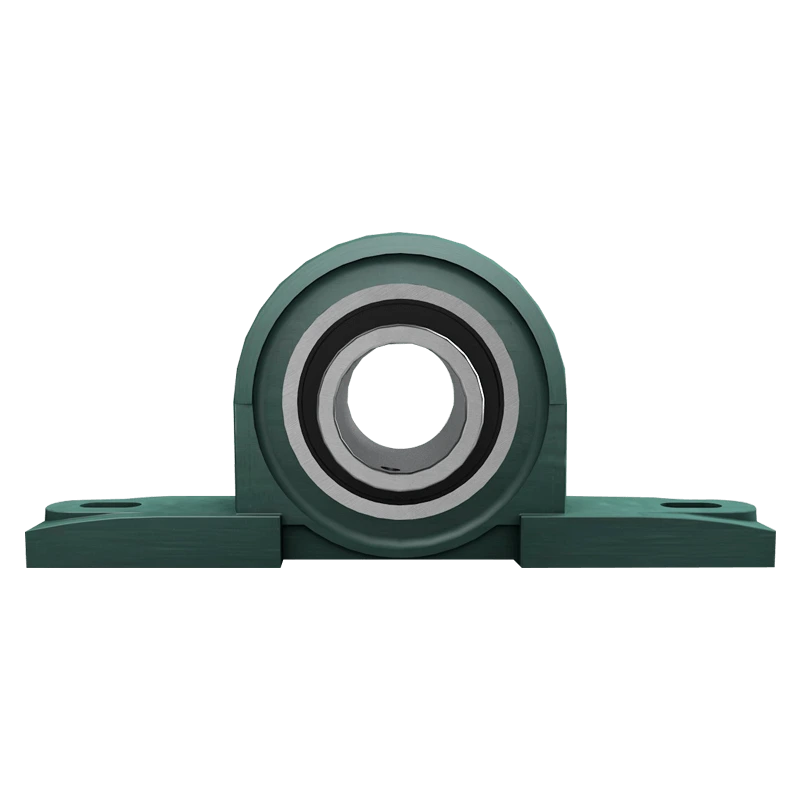

Pillow Block Bearing

A pillow block bearing supports and protects a bearing, keeping it securely aligned for reliable operation.

Structural Features

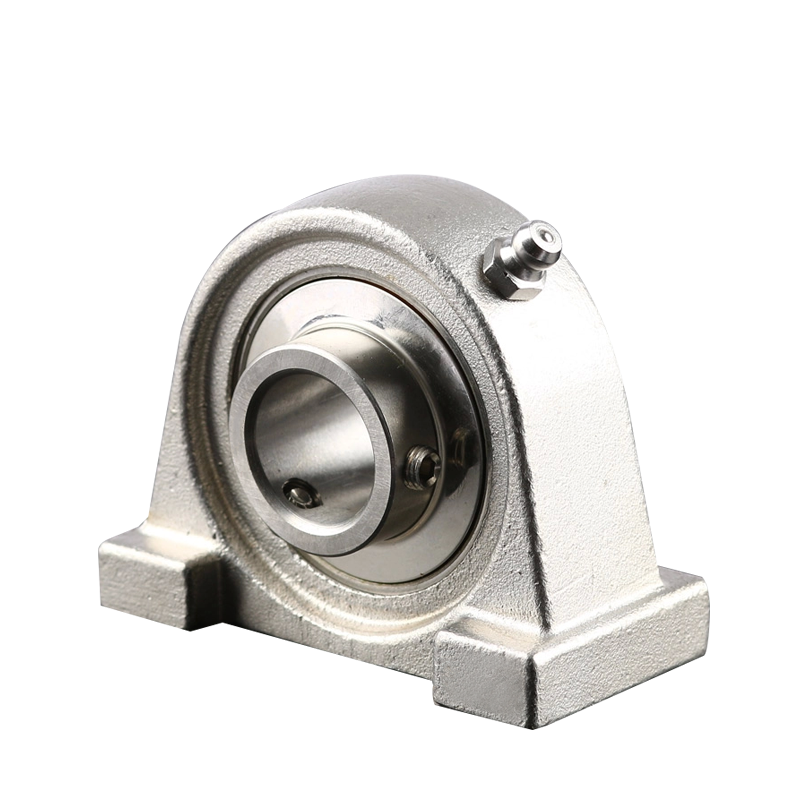

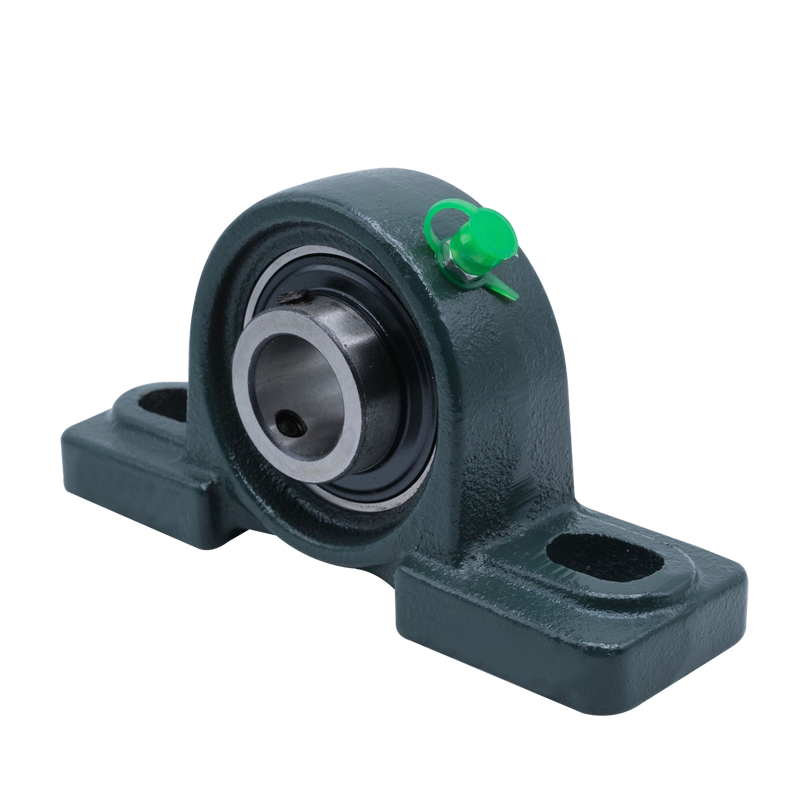

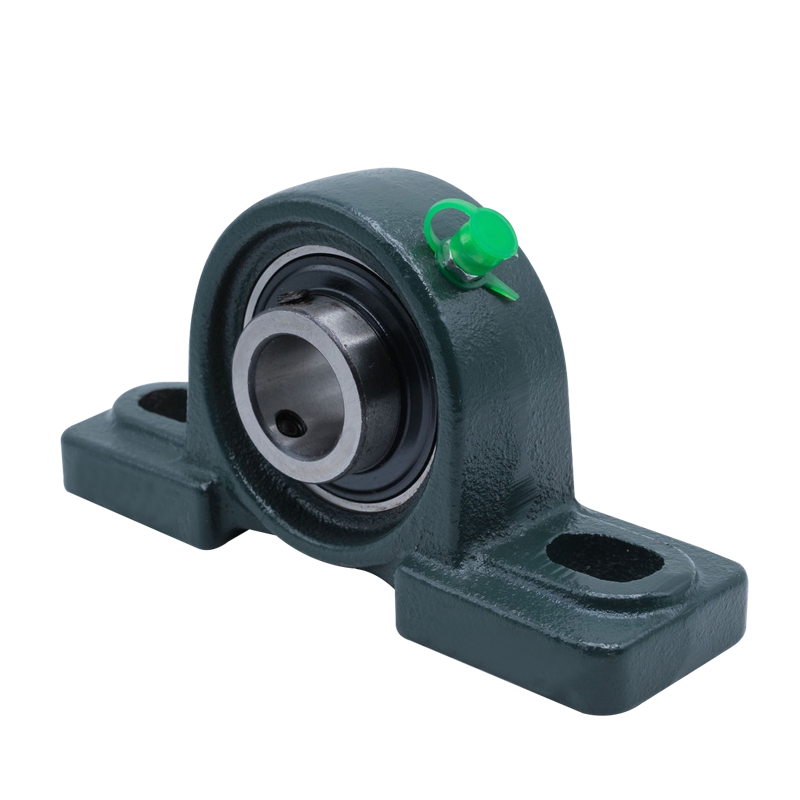

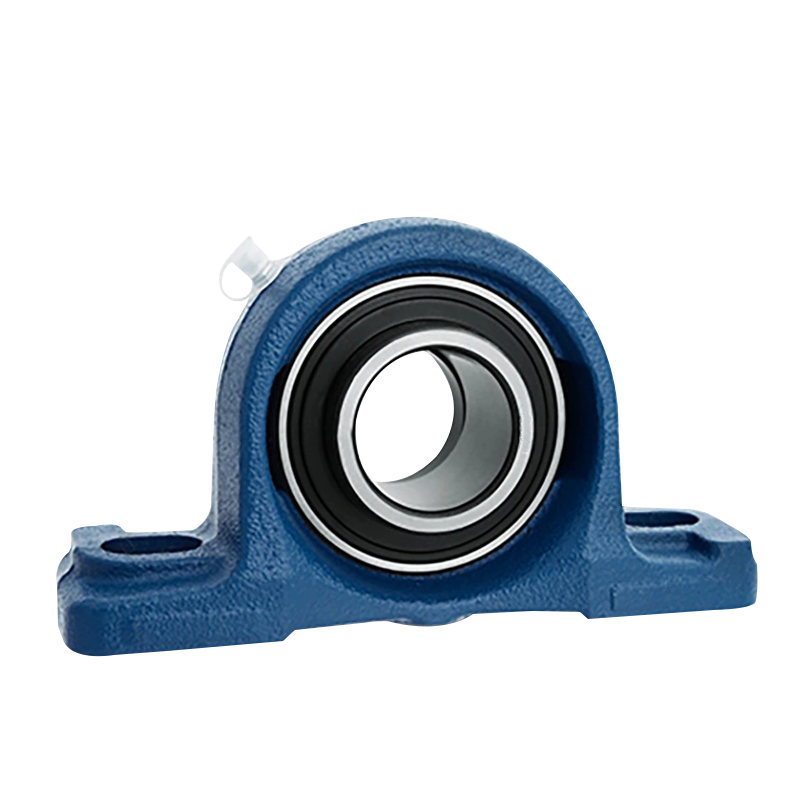

Tailored Design: The housing is designed for specific bearing types, such as ball or roller bearings, ensuring proper installation and reliable operation.

Durable Materials: Typically made from cast iron or steel for strength and rigidity; stainless steel or engineered plastics may be used for special environmental requirements.

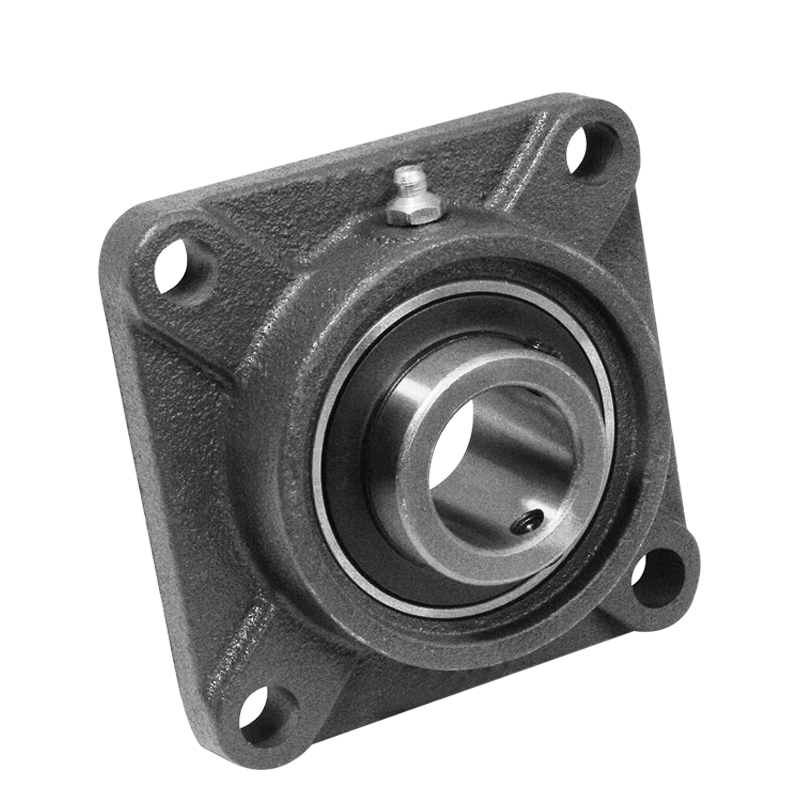

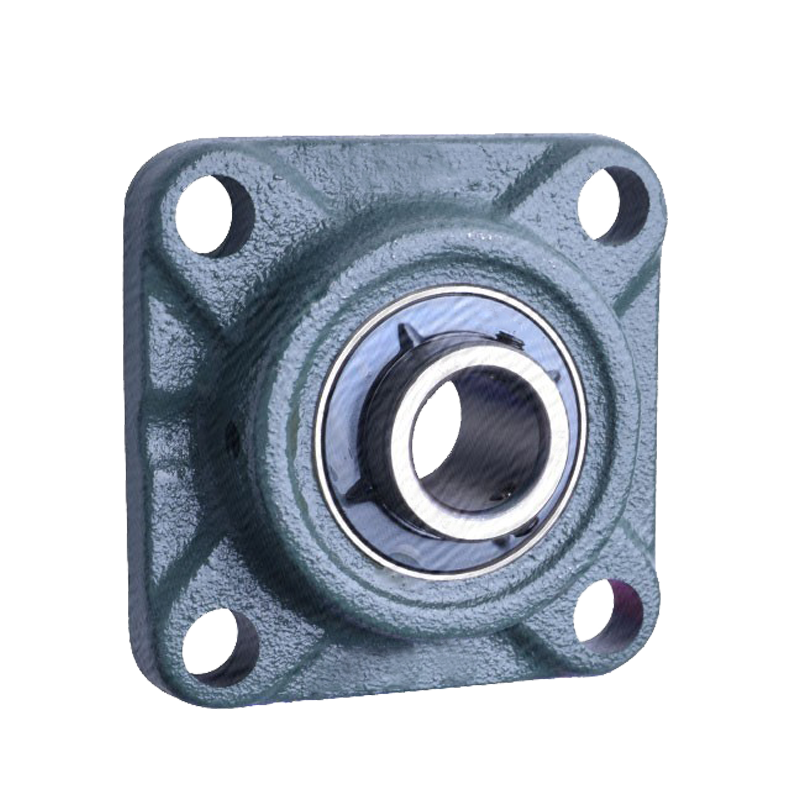

Flexible Installation: Supports multiple mounting options, including base, flange, or hanging types, to suit diverse installation needs.

Effective Sealing: Fitted with seals, such as oil seals or cover plates, to prevent dust, moisture, and contaminants from entering the bearing.

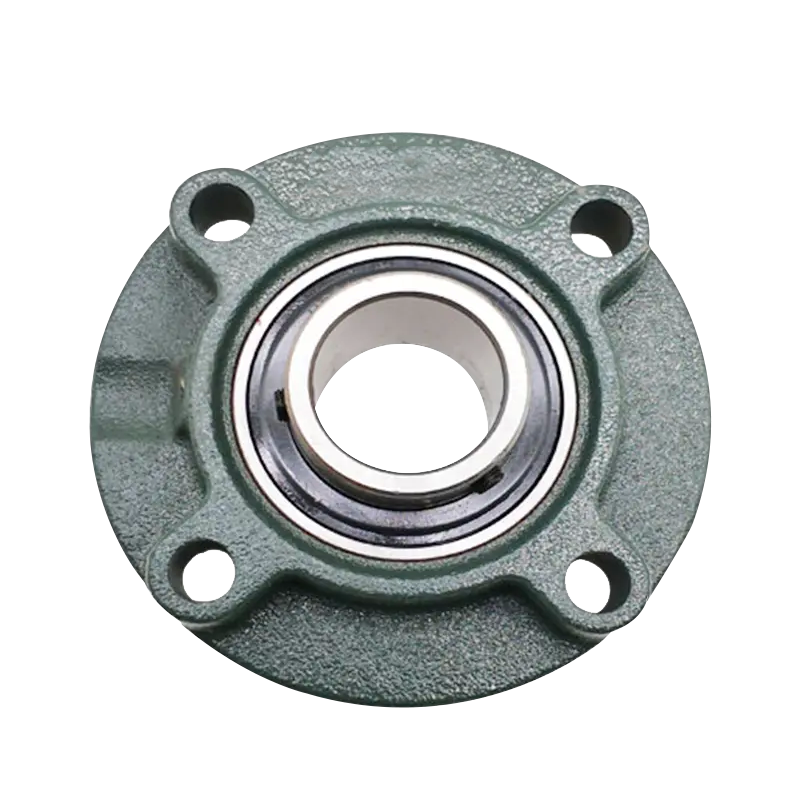

Structure Type

Bearing Unit with Round. Housing C, CX-UCC

Application Areas

Industrial Equipment: Bearing housings secure bearings in machinery such as conveyor systems, motors, and fans, ensuring smooth and reliable operation.

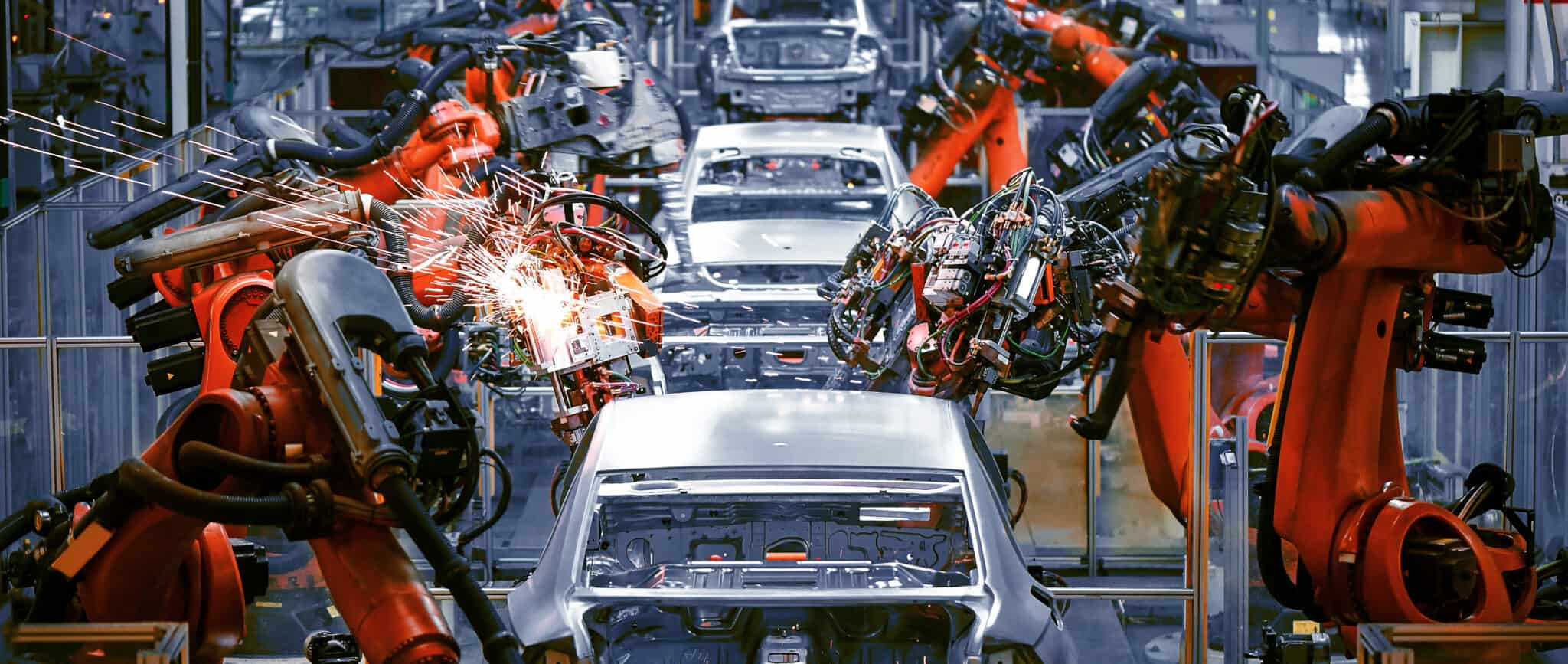

Automotive Industry: Widely used in vehicle transmission and suspension systems to provide stable bearing support and enhance performance.

Agricultural Machinery: In tractors, harvesters, and other farm equipment, bearing housings endure high loads and harsh conditions.

Construction and Heavy Machinery: Designed for excavators, cranes, and other heavy equipment, they withstand extreme loads and demanding environments.

Key Design Features

Easy Installation & Maintenance: Engineered for quick assembly and removal, reducing maintenance time and costs.

High Adaptability: Some housings allow fine adjustment of bearing position after installation for optimal performance.

Robust Load Capacity: Built with strength and rigidity to support heavy loads, enhancing equipment durability.

Versatile Sealing Options: Various sealing solutions, including dustproof, waterproof, and corrosion-resistant, to suit different operating environments.

Engineering Advantages

Bearing Protection: Shields bearings from dust, moisture, and other contaminants, extending service life.

Operational Stability: Provides a secure mounting base to maintain accuracy and reliability of mechanical systems.

Environmental Adaptability: Suitable for complex and harsh conditions, ensuring continuous operation of machinery.

Simplified Maintenance: Designed for easy upkeep, minimizing downtime and repair costs.

Equivalent to Leading Global Brands

SKF (Sweden)

Timken (USA)

NTN (Japan)

FAG (Germany)

NSK (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours