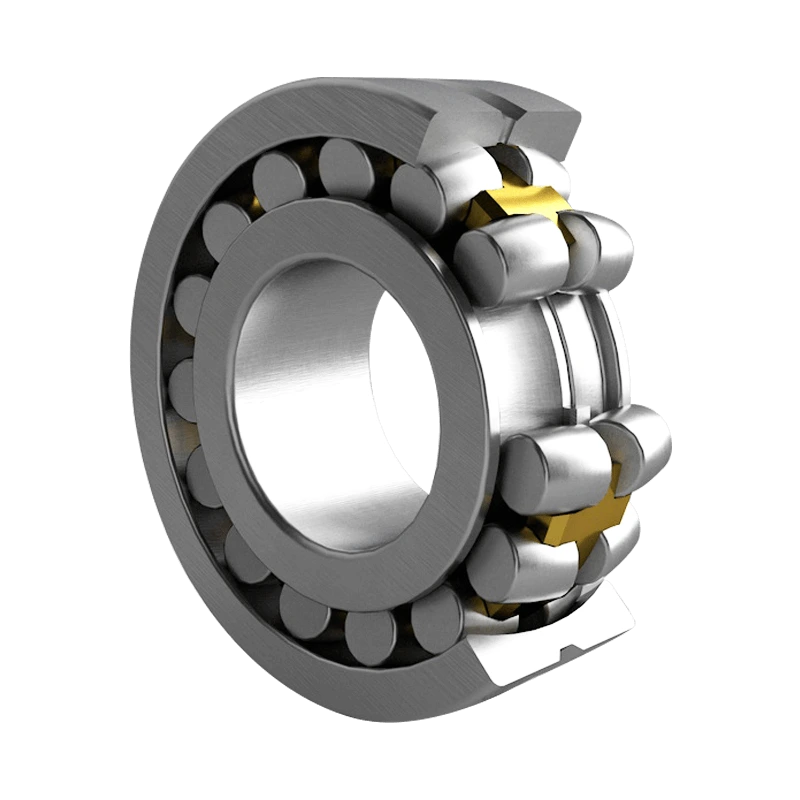

Spherical Roller Bearing

Handles heavy loads and self-aligns for shaft misalignment.

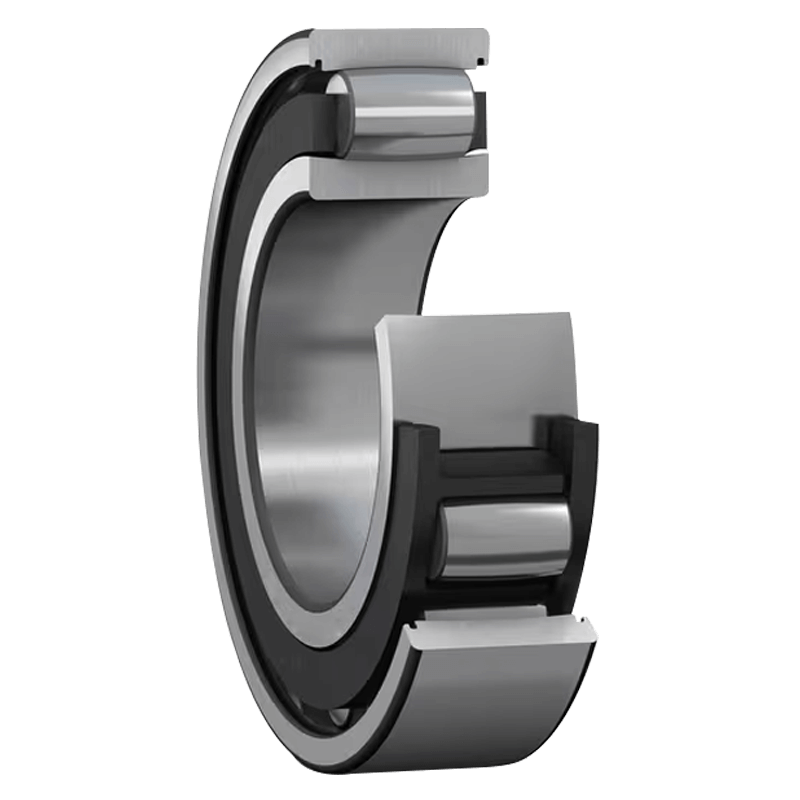

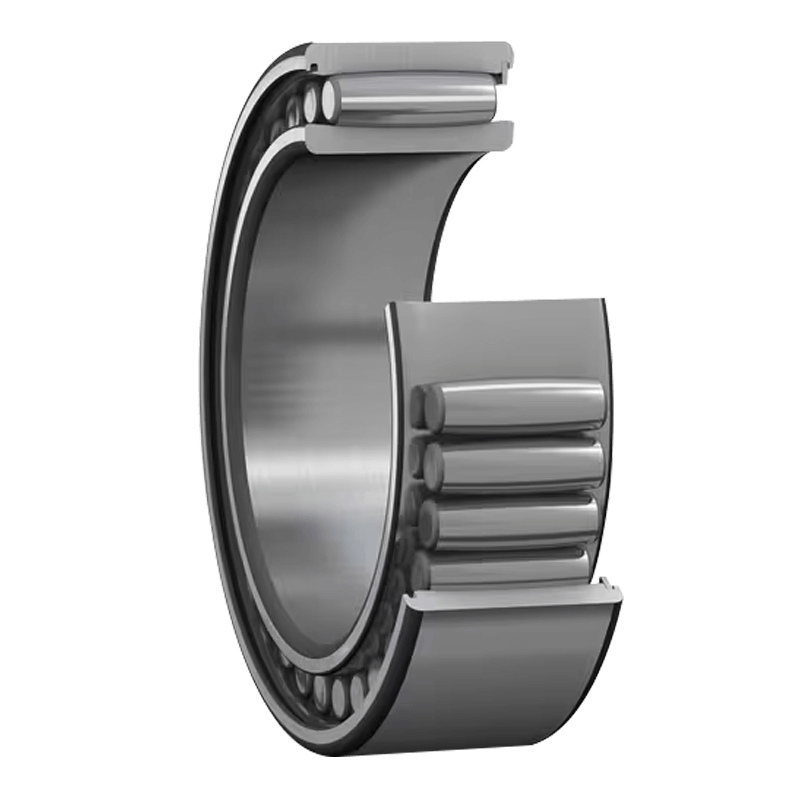

Structural Features

Two Rows of Rollers: Symmetrical roller arrangement increases load capacity.

Spherical Raceways: Outer ring allows self-alignment for shaft misalignment or bending.

Barrel Rollers: Larger contact area reduces stress and enhances load capacity.

Inner Ring Design: Dual raceways correspond to the two roller rows for stable operation.

Structure Type

Application Environment

Heavy Industry: Rolling mills, crushers, cement mills requiring high load and shaft deflection tolerance.

Wind Power: Gearboxes and generators with variable loads and misalignment.

Paper Machinery: Drying drums handling heavy loads and high temperatures.

Marine: Propulsion systems exposed to heavy loads and saltwater corrosion.

Design Features

Self-Aligning: Compensates for shaft misalignment or bending.

High Load Capacity: Barrel rollers and dual raceways support heavy radial and axial loads.

Durable & Reliable: Long-lasting operation in demanding environments.

Flexible Sealing & Lubrication: Options for various operating conditions.

Engineering Solutions

Correct Alignment Errors: Reduces maintenance and improves efficiency.

Handle Heavy Loads: Suitable for demanding, high-load applications.

Adapt to Harsh Environments: Performs in high temperature, polluted, or humid conditions.

Extend Equipment Life: Minimizes wear on shafts and components.

Equivalent to Leading Brands

SKF (Sweden)

FAG (Germany)

NSK (Japan)

Timken (USA)

NTN (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

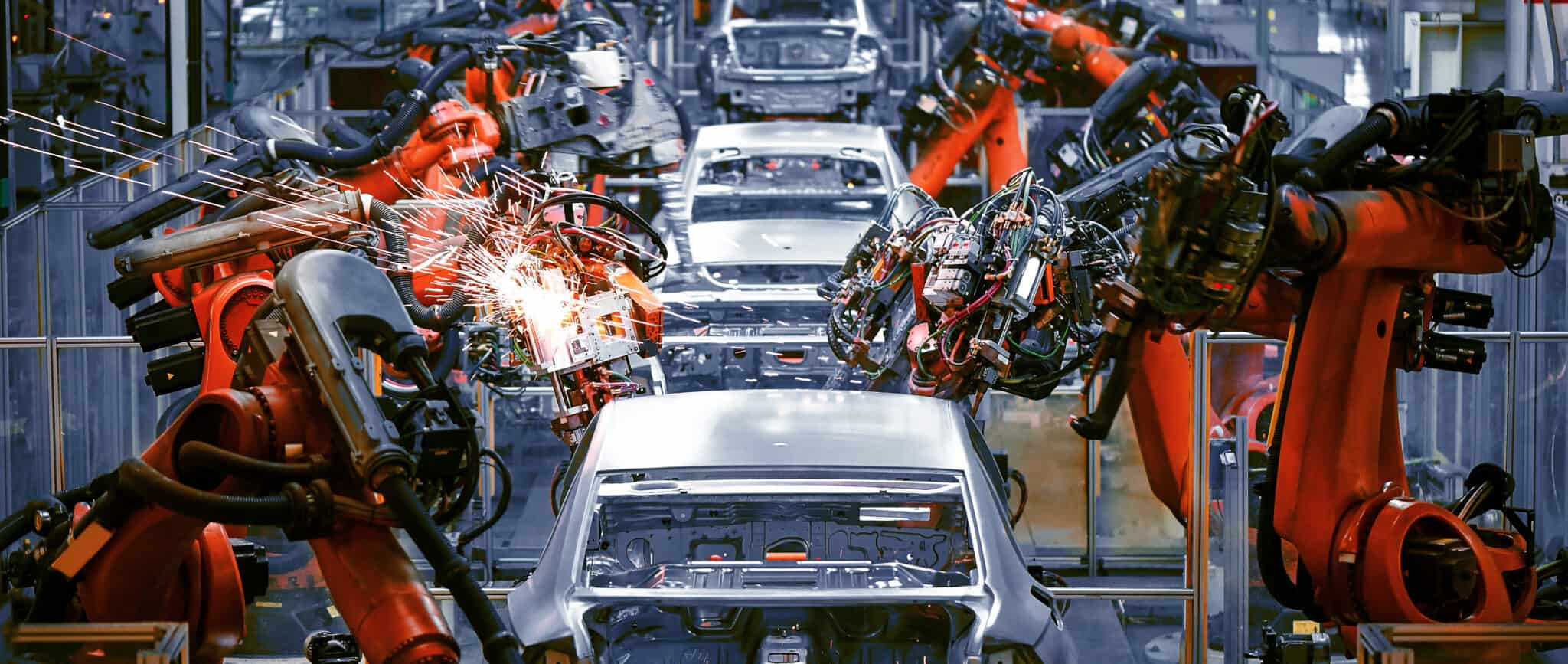

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours