Tapered Roller Bearing

Reliable, High-Precision Bearings for Industrial Applications

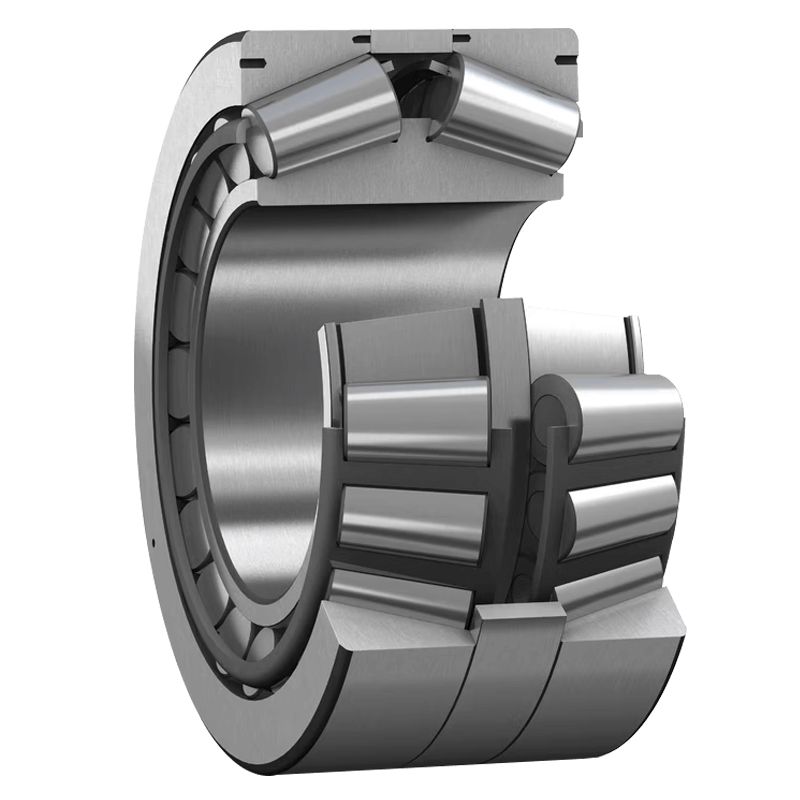

Structural Features

Conical Rollers: The rollers are conical, efficiently distributing radial and axial loads.

Inner and Outer Rings: The tapered inner ring and cup-shaped outer ring provide matching raceways for optimal contact and load transfer.

Cage: Maintains uniform roller spacing, ensuring stability and smooth operation.

Adjustable Design: Internal structure allows fine adjustments during installation to optimize load distribution and extend service life.

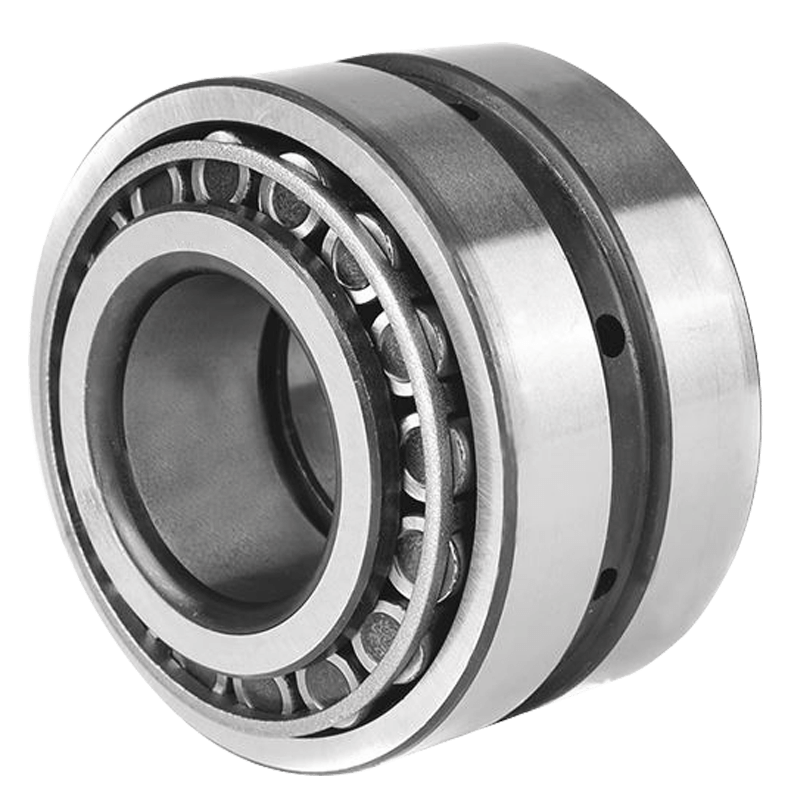

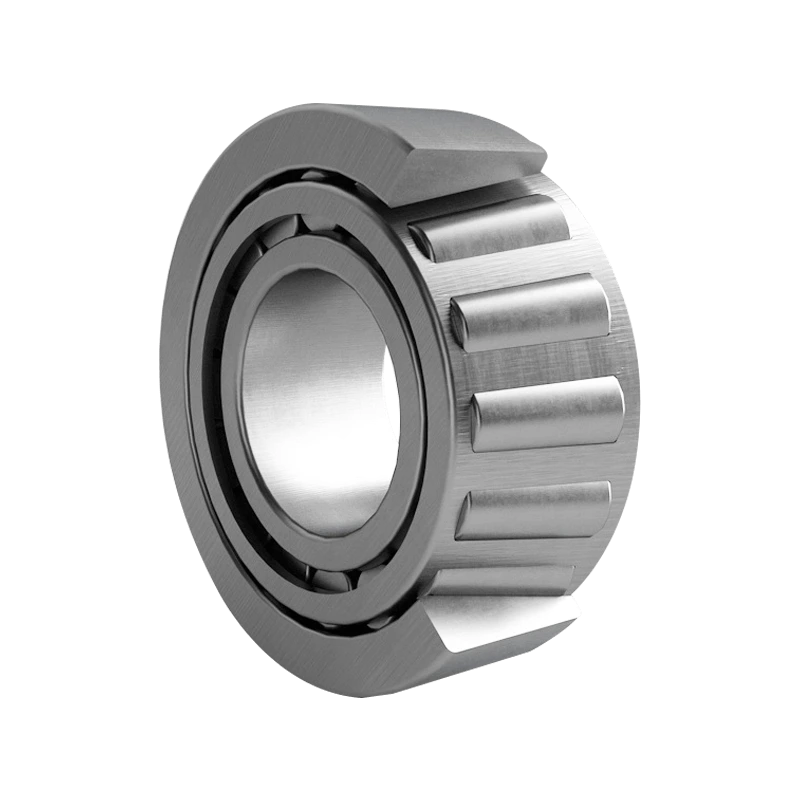

Structure Type

Application Environment

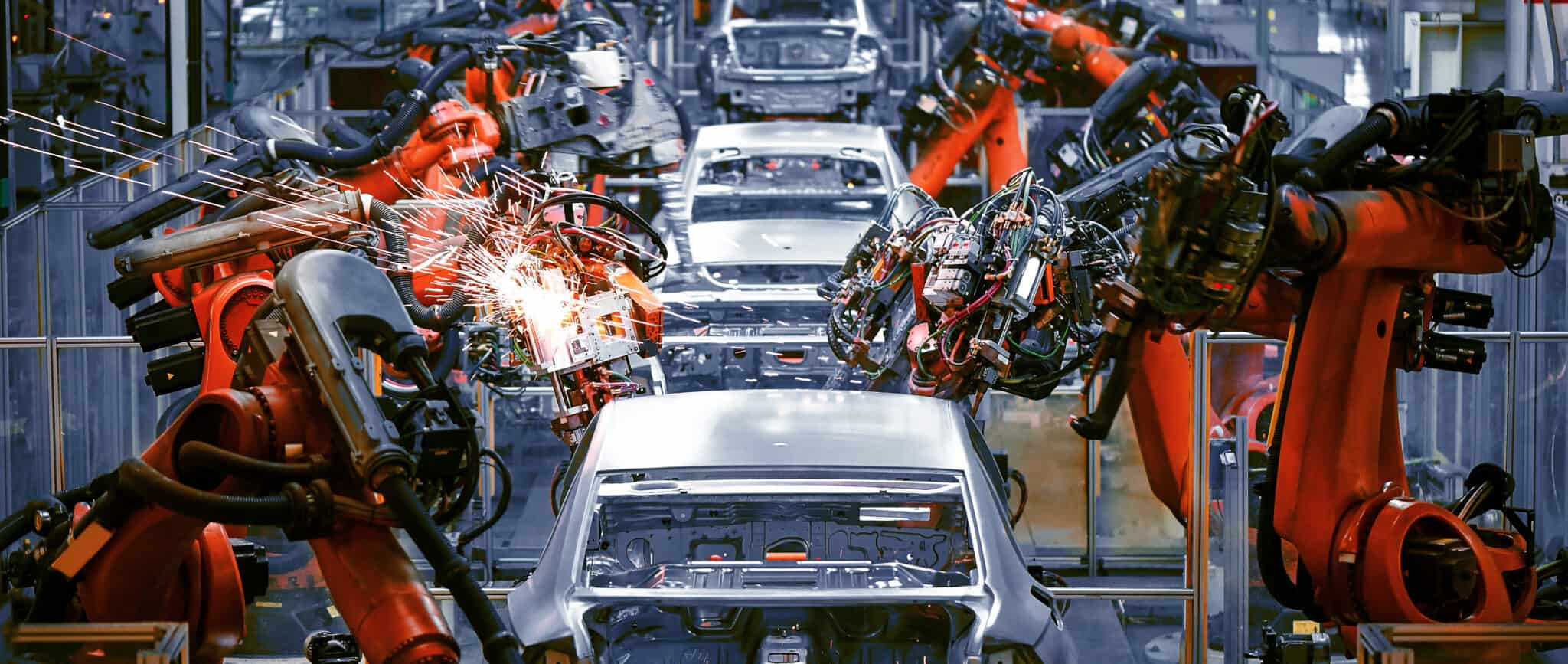

Automotive: Ideal for axles, transmissions, and differentials in trucks, handling heavy loads and shocks.

Industrial Machinery: Used in gear units, transmission systems, and other load-bearing mechanisms under complex or variable loads.

Agricultural Equipment: Suitable for tractors, harvesters, and machinery exposed to heavy loads and harsh environments.

Wind Power: Applied in wind turbine spindles and gearboxes to cope with high loads and variable-speed conditions.

Design Features

High Load Capacity: Structural design ensures stability and efficiency under high radial and axial loads.

Impact Resistance: Tapered rollers help disperse forces, improving durability in harsh environments.

Load Adaptability: Various sizes and designs allow optimized load distribution for different applications.

Maintainability: Easy installation and disassembly facilitate inspection and replacement.

Engineering Solutions

Enhanced Load Efficiency: Optimized designs improve performance under complex load conditions.

Adaptation to Harsh Environments: Special materials and sealing systems enable operation in dust, moisture, and contaminated conditions.

Reduced Maintenance: Designed for easy maintenance to lower long-term operating costs.

Improved Mechanical Performance: Reliable bearing solutions enhance overall system performance and durability.

Equivalent to Leading International Brands

Timken (USA)

SKF (Sweden)

NSK (Japan)

FAG (Germany)

NTN (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours