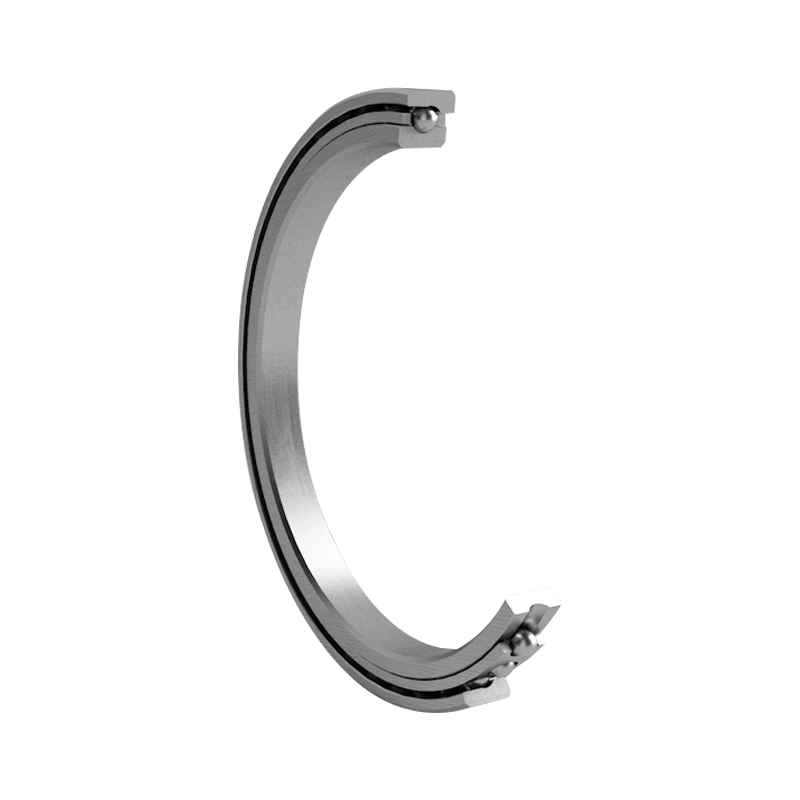

Thin Section Ball Bearing

offer space saving, lightweight design, and high precision.

Structural Features

Ultra-Thin Profile: Minimal wall thickness reduces radial space while maintaining structural strength and smooth operation.

Constant Cross-Section: Identical cross-section across all diameters simplifies design and ensures consistent performance.

Lightweight & High Strength: Manufactured from high-grade alloy steels or advanced materials to achieve low weight with excellent load capacity.

Multiple Configurations: Available in deep groove, four-point contact, and angular contact designs to suit various load directions and motion requirements.

Structure Type

Application Areas

Aerospace: Ideal for satellites, spacecraft, and aircraft components where space is limited and weight must be minimized.

Robotics: Perfect for robotic joints and precision actuators requiring high accuracy and smooth motion.

Medical Devices: Suited for surgical robots, imaging systems, and other compact medical equipment demanding reliability.

Precision Instruments: Supports optical devices, measurement tools, and other equipment where compact size and high precision are essential.

Industrial Automation: Applicable to CNC machinery, high-speed spindles, and automation equipment needing lightweight, precise bearings.

Design Advantages

High Performance: Despite the slim profile, bearings maintain excellent load capacity and rigidity.

Compact & Space-Saving: Thin-walled, constant cross-section design fits tight mechanical layouts.

Lightweight: Advanced materials reduce overall weight, improving efficiency in aerospace, robotics, and mobile systems.

Versatile: Can handle radial, axial, or combined loads, suitable for various motion requirements.

Durable & Reliable: High-strength materials and precision manufacturing ensure long service life under demanding conditions.

Engineering Solutions We Provide

Optimize Space: Install bearings in constrained spaces without sacrificing performance.

Reduce Weight: Lower equipment weight for improved mobility, energy efficiency, and reduced operational costs.

Simplify Design: Streamline assembly and mechanical design thanks to compact, uniform cross-section bearings.

Enhance Precision: Perfect for high-tech instruments and devices requiring stable and accurate motion control.

Customization Available: Bearings can be tailored in size, material, and design to meet specific application requirements.

Brand Equivalents

Our thin section bearings are high-quality alternatives to top global brands:

● Kaydon (USA)

● NTN (Japan)

● SKF (Sweden)

● Schaeffler / FAG (Germany)

● Timken (USA)

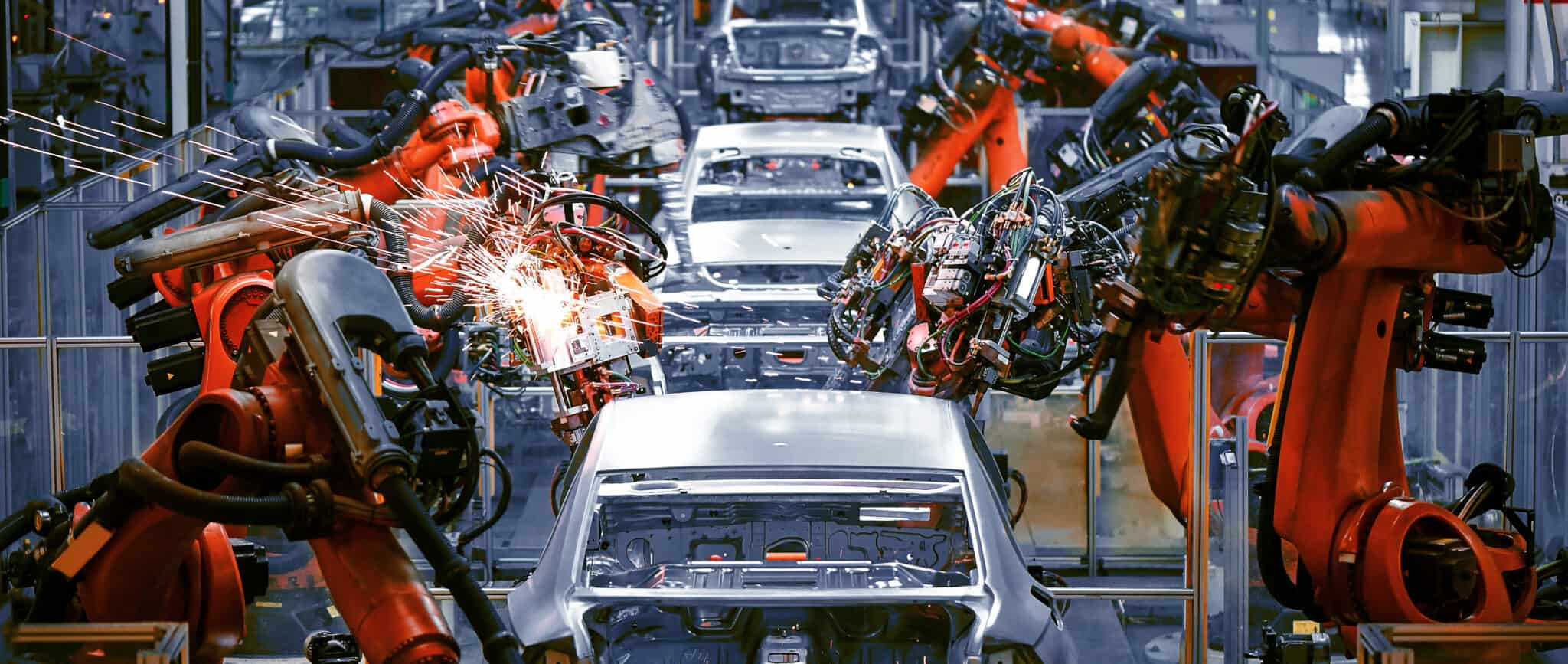

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours