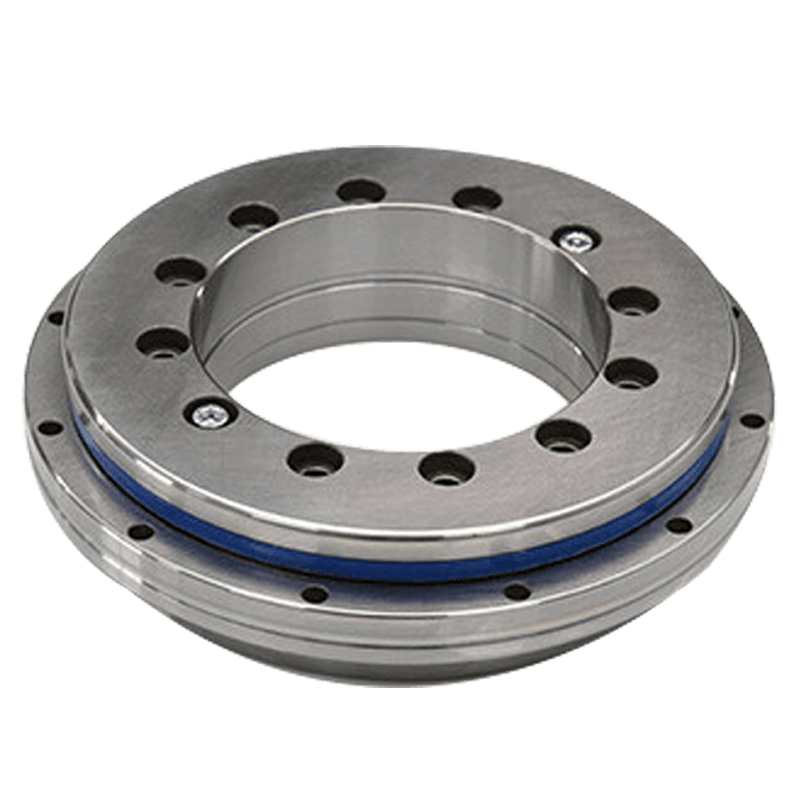

YRT Bearings

YRT bearings are compact crossed roller bearings offering smooth, precise rotation with high load capacity.

Structural Features of YRT Bearings

High Precision: Engineered for slewing applications, YRT bearings provide excellent rotational accuracy and stability.

Multi-Directional Load Support: Capable of handling axial, radial, and tilting moment loads simultaneously, suitable for complex load conditions.

Integrated Design: Combines inner and outer rings with precision rolling elements, simplifying installation and saving space.

Optimized Rolling Elements: Specially arranged rollers reduce friction and heat, improving load capacity, efficiency, and operational stability.

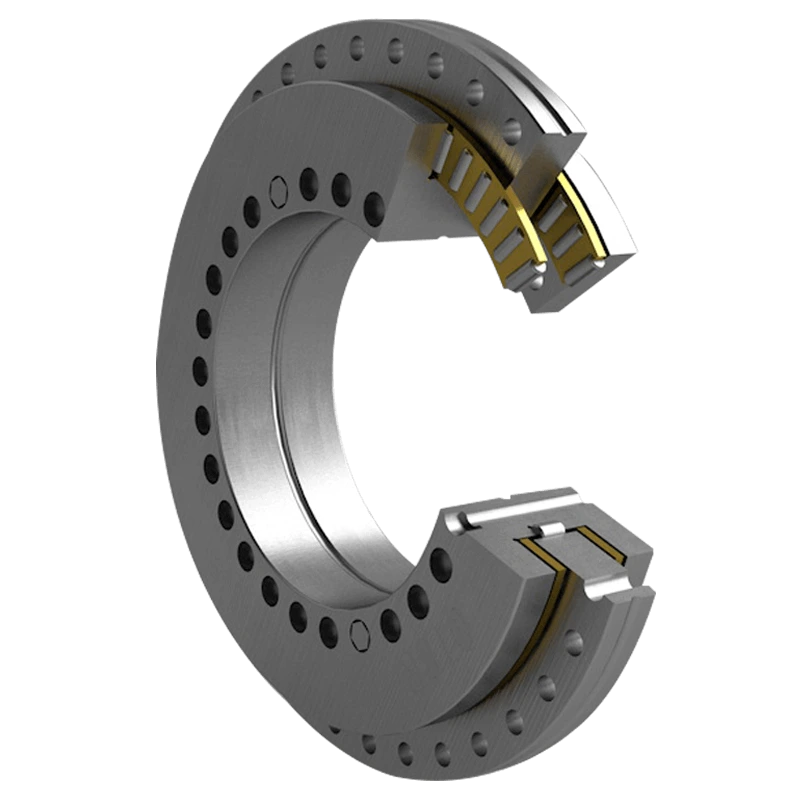

Structure Type

Application Environments

YRT bearings are ideal for slewing and rotary systems requiring high precision, low friction, and reliable load support. Typical applications include:

Machine Tools: CNC machines, lathes, and grinding machines benefit from precise spindle rotation and stability.

Optical & Precision Instruments: Microscopes, projectors, and other high-precision devices requiring smooth, accurate rotation.

Radar & Antenna Systems: Ensures stable, precise rotation of radar and antenna platforms.

Rotary Tables & Test Equipment: Provides smooth motion with reduced friction and heat, supporting high load capacities.

Robotics & Automation: Supports robotic arms and turntables in industrial and medical applications requiring precise rotation and load handling.

Key Design Features

Multi-Point Contact: Evenly distributed contact points allow uniform load distribution and high stability.

High Load Capacity: Handles axial, radial, and tilting moment loads simultaneously, suitable for complex load conditions.

Low Friction & High Rigidity: Optimized design reduces energy loss while improving precision and rotational stiffness.

Durable & Long-Lasting: Advanced materials and precision manufacturing extend service life and reduce maintenance needs.

Compact & Integrated: Combines rings and rolling elements in one design, saving space and simplifying installation.

Design Advantages

Enhanced Accuracy & Stability: Maintains precise rotation, minimizing deviations in rotary applications.

Reduced Friction & Heat: Increases efficiency and prolongs equipment life.

High Load Handling: Supports multi-directional loads for demanding working conditions.

Space-Saving Design: Integrated structure reduces component count and system complexity.

Reliable Performance in Harsh Environments: Suitable for high-speed, high-load, or precision-demanding applications.

Leading Global YRT Brands

● SKF (Sweden)

● NSK (Japan)

● FAG (Germany)

● IKO (Japan)

● Timken (USA)

● Schaeffler (Germany)

● JTEKT (Japan)

Bearing Solutions for Every Industrial Application

High-precision bearings engineered for landing gear, flight control systems, and satellites—ensuring reliability and performance in extreme conditions.

Norvda provides precision bearings for the energy sector, ensuring efficiency, durability, and reliable operation in wind power, solar systems, and power plant equipment.

Durable bearings for excavators, cranes, and other heavy machinery—engineered to handle extreme loads and harsh industrial conditions.

Norvda delivers reliable automotive bearings that support rotational motion, minimize friction, and improve the performance and lifespan of vehicles.

High-performance bearings for trains and subway systems—ensuring smooth operation, durability, and reliability under heavy loads.

Norvda delivers high-performance marine bearings that withstand heavy loads, corrosion, and continuous operation, ensuring safe and efficient vessel performance.

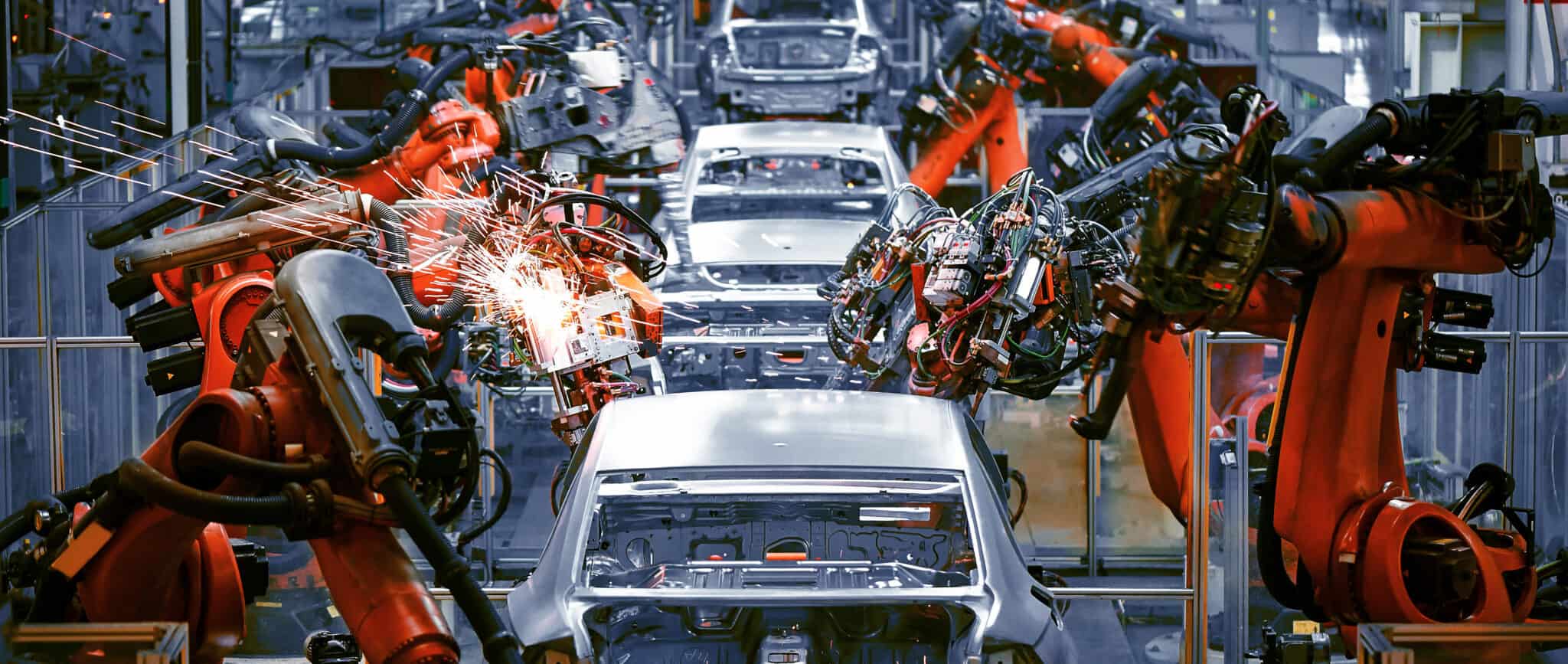

Norvda delivers precision bearings for industrial robots, supporting smooth rotation, reduced wear, and enhanced performance in automated production.

Norvda bearings are essential in semiconductor and precision electronic equipment, including hard drives, printers, and optical drives. They provide high-precision rotation, reliability, and long service life in sensitive manufacturing environments.

Norvda delivers precision bearings for medical equipment, supporting stable operation and high reliability in sensitive healthcare environments.

Contact Us

Send Us Your Inquiry — We’ll Reply Within 24 Hours