Are you tired of machine breakdowns? Do you wonder why your equipment struggles? Poor bearing choices often cause these problems.

Ball bearings reduce friction and support rotating parts. They ensure smooth operation in many machines. Understanding them improves equipment performance.

My journey began with a simple question: “How can we make things move better?” This question led me to the world of bearings.

What Are Ball Bearings and How Do They Work?

Ball bearings are small but mighty. They are essential machine parts. They allow things to spin with ease.

Ball bearings use metal balls to reduce friction between moving parts. This design allows smooth rotation. They support radial and axial loads.

Let me tell you a quick story. Years ago, my grandfather’s old farm machinery constantly broke down. We discovered worn-out bearings were the problem. Replacing them transformed the machine. This experience taught me the real value of good bearings.

Dive Deeper: The Inner Workings of Ball Bearings

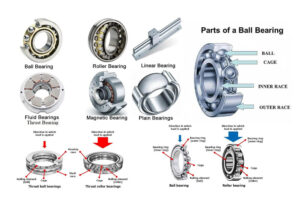

A ball bearing has four main components. Each part plays a key role.

- Outer Race: This is the stationary ring. It surrounds the balls. It allows the inner race to spin inside it.

- Inner Race: This is the rotating ring. It fits over the shaft. It spins with the shaft.

- Balls: Small, hardened steel balls sit between the races. They carry the load. They roll to reduce friction.

- Cage (Retainer): This keeps the balls spaced evenly. It prevents them from touching each other. This reduces heat and wear.

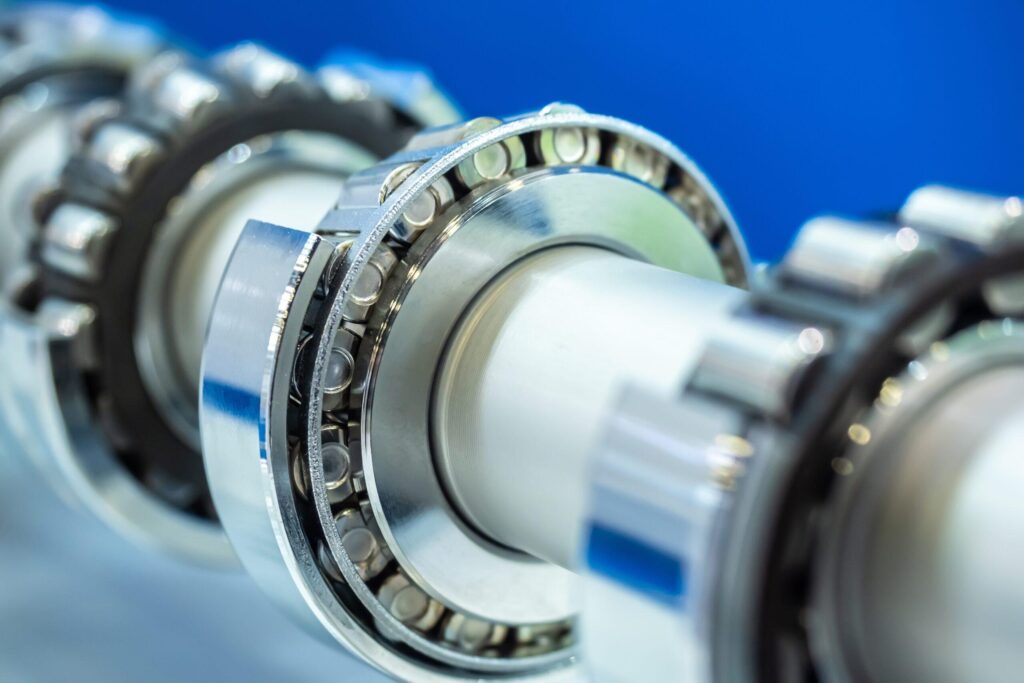

Imagine a heavy wheel. Without bearings, it would drag. Bearings let it roll smoothly. The balls act as tiny rollers. They transfer the load from one race to another. This turns sliding friction into rolling friction. Rolling friction is much lower. This saves energy. It also reduces wear on parts.

Consider the forces acting on a bearing. A radial load pushes on the side. An axial load pushes along the shaft. Ball bearings handle both. The balls distribute these forces. They prevent damage to the machine. Proper lubrication is also vital. It creates a film between the balls and races. This film further reduces friction. It prevents metal-on-metal contact.

This design makes ball bearings versatile. They are in many everyday items. From skateboard wheels to washing machines, bearings are working. They make life smoother.

Where Are Ball Bearings Commonly Used?

Ball bearings are everywhere. You might not see them. But they are working hard.

Ball bearings are used in cars, bicycles, home appliances, and industrial machinery. They enable smooth movement. They support rotating parts in many applications.

We often get questions from customers. They ask about specific applications. One customer needed bearings for a new conveyer belt system. We helped them choose the right type. The system ran perfectly. This is why understanding usage is vital.

Dive Deeper: Specific Applications and Their Demands

Different applications have different needs. The bearing type must match the job.

- Automotive Industry: Cars use many bearings.

- Wheels: Bearings allow wheels to spin freely. They handle heavy loads. They endure high speeds.

- Engines: Bearings support crankshafts and camshafts. They ensure smooth power delivery.

- Transmissions: Bearings enable gear changes. They reduce friction between gears.

- Steering Systems: Bearings here allow for precise control.

- Industrial Machinery: Factories rely on bearings.

- Conveyor Belts: Bearings support the rollers. They keep production lines moving.

- Pumps: Bearings support pump shafts. They ensure efficient fluid transfer.

- Motors: Bearings support motor shafts. They allow for consistent rotation.

- Gearboxes: Bearings in gearboxes reduce friction. They help transmit power.

- Home Appliances: Even inside your home, bearings are working.

- Washing Machines: Bearings support the drum. They allow it to spin at high speeds. This is crucial for clothes drying.

- Vacuum Cleaners: Bearings support the motor. They help the brushes spin.

- Dishwashers: Bearings support various rotating parts. They ensure quiet operation.

- Sports Equipment: From leisure to professional use, bearings are key.

- Bicycles: Bearings are in the wheels, pedals, and bottom bracket. They make cycling efficient.

- Skateboards: Bearings in the wheels allow for smooth gliding.

- Fishing Reels: Small, precise bearings ensure smooth line retrieval.

Each application has unique environmental factors. These include temperature, dust, and moisture. The right bearing can resist these challenges. For example, a bearing for a food processing plant might need special seals. This prevents contamination. A bearing in a high-temperature furnace needs heat-resistant materials. Choosing the precise bearing ensures reliability and longevity. This saves time and money.

What Are the Different Types of Ball Bearings?

Not all ball bearings are the same. They come in various forms. Each type serves a specific purpose.

Different ball bearing types include deep groove, angular contact, thrust, and self-aligning bearings. Each is designed for specific load types and applications.

When I started our business, I thought “a bearing is a bearing.” I was wrong. Understanding the distinctions between types was a game-changer. It helps us serve our customers better.

Dive Deeper: Choosing the Right Bearing Type

Selecting the right bearing is crucial. It impacts performance and lifespan.

- Deep Groove Ball Bearings (DGBB):

- Characteristics: These are the most common type. They have deep raceway grooves. This allows for high radial and moderate axial loads.

- Applications: Motors, gearboxes, home appliances, automotive transmissions. They are versatile and reliable.

- Angular Contact Ball Bearings:

- Characteristics: These bearings have raceways offset from each other. They handle combined radial and high axial loads in one direction. They often come in pairs to support axial loads in both directions.

- Applications: Machine tool spindles, pumps, compressors. They provide high precision and rigidity.

- Thrust Ball Bearings:

- Characteristics: These bearings are designed for axial loads only. They handle forces pushing along the shaft. They do not handle radial loads well.

- Applications: Turn tables, crane hooks, automotive steering mechanisms. They ensure smooth rotation under direct axial pressure.

- Self-Aligning Ball Bearings:

- Characteristics: These bearings have two rows of balls and a common spherical outer raceway. This allows them to compensate for shaft misalignment.

- Applications: Agricultural machinery, fans, textile machinery. They are useful when alignment issues may occur.

- Miniature Ball Bearings:

- Characteristics: These are very small. They have precise dimensions. They are for compact spaces.

- Applications: Medical instruments, tiny motors, precision electronics.

- Ceramic Bearings:

- Characteristics: Made from ceramic materials. They are lighter, stiffer, and run cooler. They are non-magnetic. They resist corrosion.

- Applications: High-speed machinery, aerospace, specialized pump applications.

Each type has design strengths and weaknesses. For instance, a deep groove bearing is excellent for general use. But for a highly precise machine tool, an angular contact bearing is better. Its ability to manage specific loads is superior. My team always starts by asking about the application’s load, speed, and environment. This helps us pinpoint the perfect bearing. It ensures optimal performance for our customers.

How Do You Maintain Ball Bearings for Long Life?

Bearings need care. Proper maintenance extends their life. It prevents costly breakdowns.

Proper ball bearing maintenance includes regular lubrication, cleaning, and inspection. These steps prevent wear and ensure long-term, reliable operation.

I’ve seen machinery fail because of simple neglect. A little care goes a long way. My first big learning experience was working on an old factory line. We noticed consistent bearing failures. It turned out to be a lubrication issue. We implemented a new greasing schedule, and the problems vanished.

Dive Deeper: Best Practices for Bearing Maintenance

Good maintenance practices are an investment. They save money in the long run.

- Proper Lubrication:

- Purpose: Lubrication reduces friction and heat. It prevents corrosion. It flushes away contaminants.

- Methods: Grease is common for sealed bearings. Oil is used for unsealed bearings. Centralized lubrication systems provide consistent supply for large machines.

- Frequency: Lubrication schedules depend on bearing type, load, speed, and environment. Too little lubrication causes wear. Too much causes overheating.

- Type of Lubricant: Choose the correct type. Some lubricants are for high temperatures. Others are for wet conditions.

- Regular Cleaning:

- Purpose: Contaminants like dust and dirt cause wear. They reduce bearing life.

- Method: Keep the bearing environment clean. Use proper seals. Clean the area around the bearing during maintenance.

- Caution: Do not use high-pressure water jets directly on bearings. This can force contaminants in. It can wash out lubrication.

- Routine Inspection:

- Purpose: Look for early signs of wear or damage. This prevents major failures.

- What to Check:

- Noise: Listen for unusual sounds like grinding or squealing.

- Temperature: Check for excessive heat. Hot bearings can mean too much friction.

- Vibration: Use vibration analysis tools. Increased vibration indicates wear.

- Visual Cues: Look for rust, discoloration, or cracks. Check for lubricant leakage.

- Frequency: Inspections should be regular. Critical machinery needs more frequent checks.

- Proper Mounting and Installation:

- Importance: Incorrect installation can cause immediate bearing failure.

- Tools: Use proper tools. Avoid direct hammering on races or balls. Use presses or induction heaters.

- Alignment: Ensure shafts and housings are aligned. Misalignment causes uneven loads. This leads to premature wear.

- Storage:

- Method: Store bearings in a clean, dry place. Keep them in their original packaging until needed. This prevents damage and contamination.

Implementing a robust maintenance program is essential. It includes scheduled checks and proper training for staff. We always advise our customers on best practices. This helps them get the most out of our bearings. It ensures their machinery runs smoothly for years.

Conclusion

Ball bearings are fundamental to modern machinery. They reduce friction. They support movement. Understanding their types, uses, and maintenance extends equipment life.