What is a Bearing?

A bearing is a machine element that enables relative motion between two parts while minimizing friction and wear. Its primary function is to support rotating shafts and other moving parts by guiding motion and bearing loads—whether radial, axial, or a combination of both. Bearings are essential components in virtually every type of machinery, including vehicles, industrial equipment, electric motors, construction machinery, and more.

Bearings ensure mechanical efficiency, precision, and longevity by allowing smooth motion under controlled constraints. Their performance has a direct impact on the reliability, durability, and performance of the machines in which they are installed.

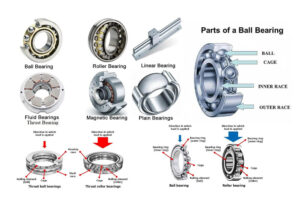

Basic Structure and Working Principle

Most bearings are made up of the following core components:

- Inner Ring: Mounted onto the rotating shaft

- Outer Ring: Fits into the housing and remains stationary

- Rolling Elements: Balls or rollers placed between the inner and outer ring

- Cage (Retainer): Maintains the spacing and alignment of rolling elements

- Seals/Shields: Prevent entry of contaminants and retain lubricant

The working principle of a bearing relies on reducing surface contact between moving parts. Rolling elements (such as balls or rollers) minimize friction by rolling rather than sliding. This helps reduce energy consumption, heat generation, and material wear, thereby extending service life and improving performance.

Types of Bearings and Their Applications

Bearings come in many forms, classified mainly by their rolling elements and the type of load they support:

1. Ball Bearings

- Structure: Spherical balls between two rings

- Load Capacity: Suitable for low to moderate radial and axial loads

- Applications: Electric motors, fans, gearboxes, household appliances

- Variants: Deep groove, angular contact, thrust ball bearings

Deep Groove Ball Bearings are the most common type, suitable for high-speed rotation and capable of handling radial and light axial loads.

Angular Contact Ball Bearings support combined loads and are commonly used in automotive and machine tool applications.

2. Roller Bearings

- Structure: Cylindrical, tapered, or spherical rollers

- Load Capacity: Higher radial load capacity than ball bearings

- Applications: Mining equipment, conveyors, pumps, heavy-duty gearboxes

Cylindrical Roller Bearings have high radial load capacity and are ideal for high-speed applications.

Tapered Roller Bearings can handle both radial and axial loads, widely used in automotive wheel hubs and gear sets.

Spherical Roller Bearings are self-aligning and ideal for applications with shaft misalignment or heavy loads, such as mining, steel mills, and wind turbines.

3. Thrust Bearings

- Function: Support axial (thrust) loads

- Types: Thrust ball bearings, cylindrical thrust, tapered thrust, and spherical thrust bearings

- Applications: Vertical pumps, turntables, automotive clutches, cranes

Thrust bearings are critical in scenarios where axial loads dominate. For example, a thrust ball bearing may be used in low-speed applications, while a spherical roller thrust bearing handles higher loads and misalignments.

4. Needle Bearings

- Structure: Long, thin cylindrical rollers

- Benefits: High load capacity in compact form

- Applications: Gearboxes, automotive transmissions, compressors, two-stroke engines

Needle roller bearings are compact and lightweight, often used where space and weight constraints are critical, but load requirements remain high.

5. Self-aligning Bearings

- Structure: Double rows of balls with a spherical outer ring raceway

- Advantages: Automatically compensates for misalignment

- Applications: Agricultural equipment, textile machinery, light machinery

These bearings help reduce installation errors and deflection issues, which can lead to premature failure in rigid bearing types.

Bearing Materials

The choice of material directly affects a bearing’s performance, durability, corrosion resistance, and temperature tolerance. Common materials include:

Bearing Steel (GCr15 / SAE 52100)

- High hardness, wear resistance, and fatigue strength

- Most commonly used in general-purpose bearings

Stainless Steel (AISI 440C, 304, 316)

- Corrosion resistance for harsh environments

- Used in food processing, marine, and chemical industries

Ceramic (Silicon Nitride or Zirconia)

- Lightweight, low thermal expansion, corrosion and heat resistant

- Used in high-speed and high-precision applications (e.g., aerospace, high-speed spindles)

Brass / Polyamide / Steel Cages

- Cages vary depending on load, temperature, and speed

- Brass for high-load and temperature, polyamide for lower noise and speed, steel for general use

Lubrication: Grease vs. Oil

Proper lubrication is vital to bearing performance:

- Grease Lubrication:

- Longer lifespan, simple maintenance

- Preferred for sealed or shielded bearings

- Suitable for moderate-speed and temperature applications

- Oil Lubrication:

- Better for high-speed, high-temperature operations

- Requires a circulating system or oil bath

- More complex to maintain

Lubrication minimizes contact between surfaces, dissipates heat, prevents corrosion, and flushes out contaminants.

Bearing Performance Indicators

When selecting or evaluating a bearing, consider the following parameters:

- Load Rating (C): Dynamic and static capacities

- Speed Rating (RPM): Maximum safe rotational speed

- Precision Grades (ABEC, ISO): Tolerance levels, crucial in high-precision machinery

- Noise & Vibration Levels: Important in electric motors, fans, and household appliances

- Temperature Range: Suitability for high or low temperature applications

- Sealing Type: Open, sealed, or shielded depending on operating environment

Bearing Failures and Causes

Common causes of bearing failure include:

- Insufficient Lubrication

- Contamination (dust, water, metal particles)

- Excessive Load

- Misalignment

- Corrosion

- Overheating

- Poor installation

Identifying and addressing these issues early can significantly extend the bearing’s service life.

Applications Across Industries

Bearings are found in almost every industry and type of machinery:

| Industry | Application |

|---|---|

| Automotive | Engines, transmissions, wheel hubs, clutches |

| Construction | Excavators, bulldozers, cranes, loaders |

| Mining | Crushers, conveyor belts, motors |

| Wind Energy | Turbine main shaft, gearbox, generator |

| Machine Tools | Spindles, linear guides, ball screws |

| Aerospace | Jet engines, landing gear, navigation systems |

| Marine | Propulsion systems, winches, steering gear |

| Agriculture | Tractors, harvesters, irrigation systems |

| Food & Beverage | Conveyor belts, mixers, sterilization equipment |

| Electrical Motors | Fans, compressors, generators |

Custom Bearing Solutions

At Siderwin, we provide customizable bearing solutions tailored to your needs. Whether you require a standard deep groove ball bearing or a complex high-load tapered roller bearing, we offer:

- Custom dimensions and tolerances

- Special materials (stainless steel, ceramics, etc.)

- Special surface treatments (coatings, anti-corrosion)

- Third-party testing & certification

- OEM & ODM services

We serve both equipment manufacturers and aftermarket clients, ensuring strict quality control at every stage.

Why Choose Us?

- ✅ German Machinery: Advanced production lines for high-precision bearings

- ✅ Quality Assurance: Full inspection and third-party testing support

- ✅ Flexible MOQ & Lead Time: For both large buyers and small orders

- ✅ Global Export Expertise: Southeast Asia, Middle East, Europe, Americas

- ✅ Engineering Support: Custom load analysis and application design

Conclusion

Bearings are the unsung heroes of machinery—small in size but massive in impact. Understanding their types, materials, structures, and performance parameters can help you select the right solution for your application. At Siderwin, we’re committed to providing durable, high-precision, and cost-effective bearing solutions that support your business.